Sanitary stainless steel mixproof butterfly valve

What is a mixproof butterfly valve?

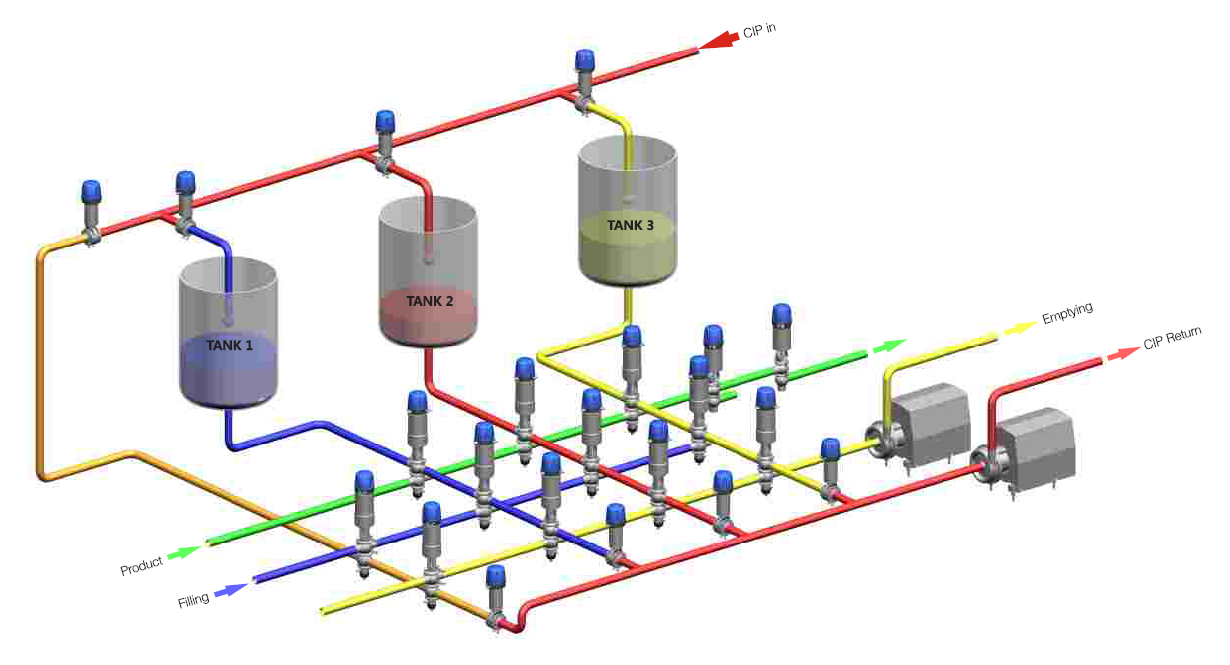

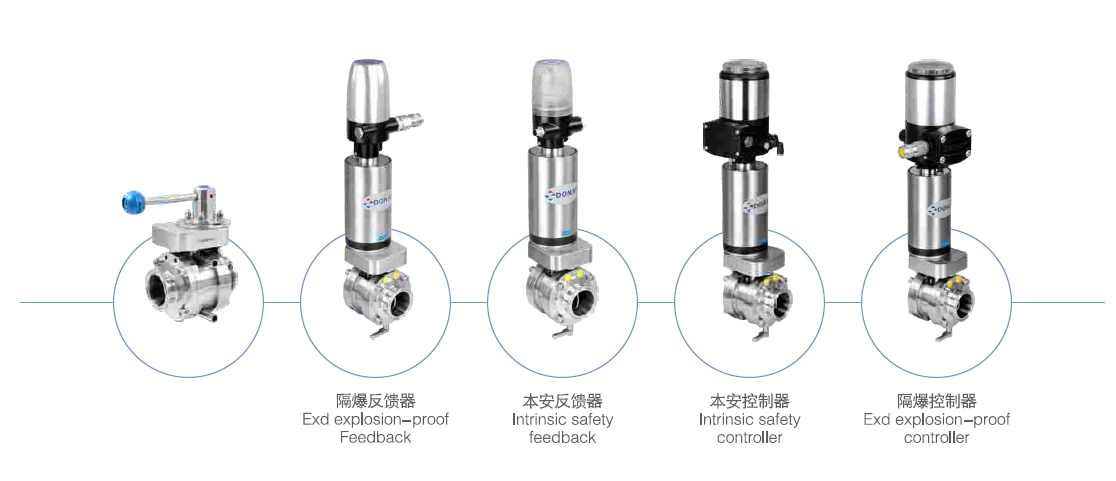

DF-FHA series mixproof double seat butterfly valve is widely used in various industrial fluid process applications such as food, pharmaceutical, beverage, beer, liquor, water treatment, cosmetics, new energy, daily washing and so on. The mixproof butterfly valve provides an easy and safe means of material separation to prevent accidental mixing of materials in the event of damage to the seal. It is most commonly used to isolate materials that require safe separation and a single set of CIP cleaning (not a valve array assembly), or into the tank assembly terminal (eg, CIP return) or CIP solution into the tank (by cleaning the ball).

Double seat seal protection, Internal leakage can be observed, Valve cavity can be cleaned, Zero pollution risk

Technical Features

Material: 304/1.4301, 316L/1.4404, ASME BPE 316L 1.4435 NB2 Fe≤0.5%

Temperature: EPDM -20℃ to +130℃, Depending on the seal material

Connection standard: DIN SMS ISO IDF RJT BS4825 ASME BPE 3A DIN11864 DIN11853

Surface: Ra≤0.8μm; MP=Ra≤0.3μm; EP=Ra≤0.3μm

Certification: FDA 177.2600; 3A-18-03; Glass II USP Glass VI Chapter 88; GB4806.11; EG VO/1935-2004; PED/97/23/EC

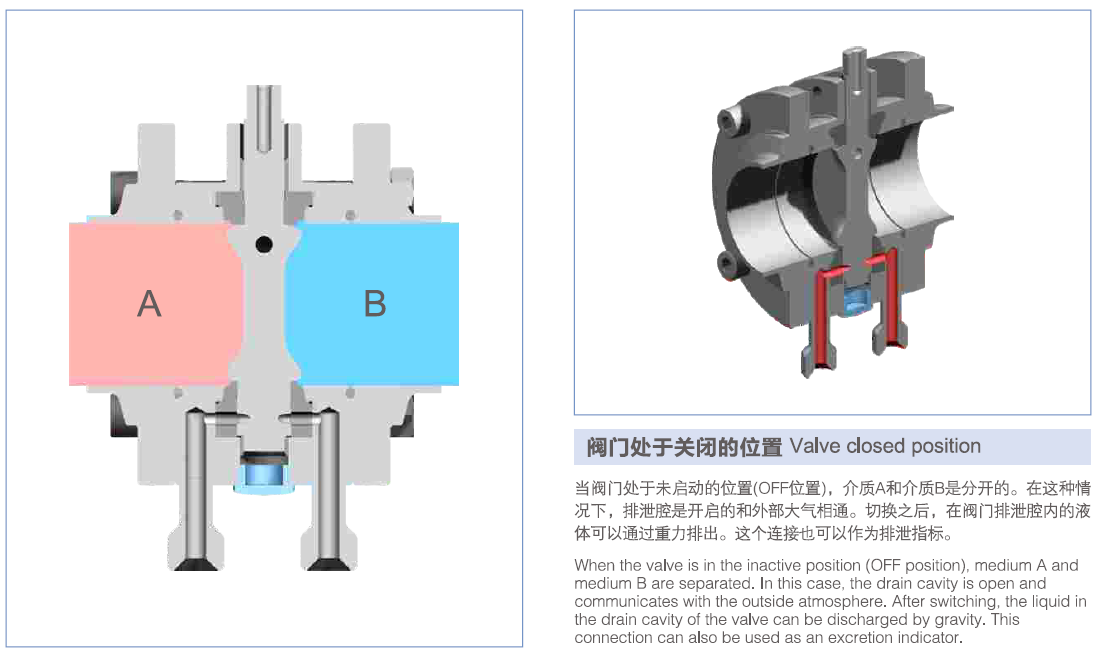

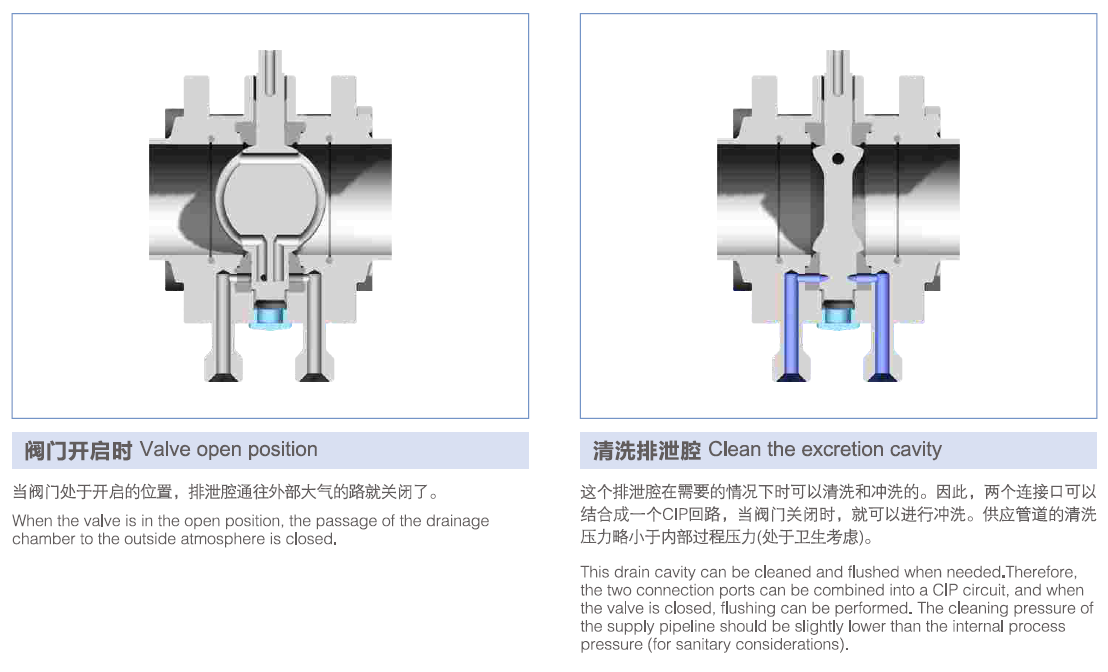

Working princple

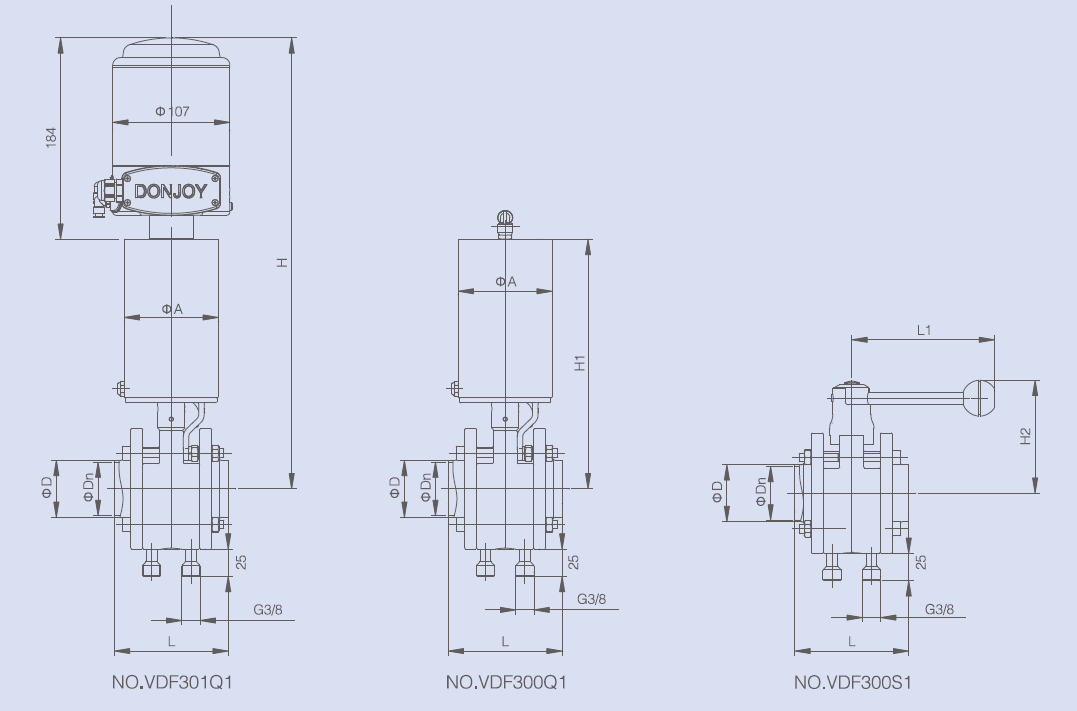

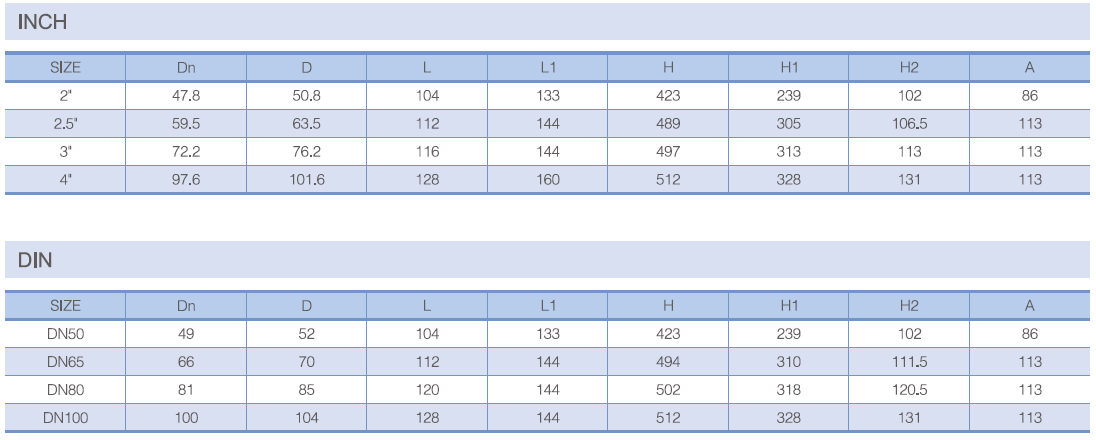

Product Drawing

Typical Application

Operating Torque(N.M)

| Operating Torque(N.M) | DN40/1.5" | DN50/2" | 2.5" | DN65 | 3" | DN80/3.5" | DN100/4" |

| 10 | 15 | 20 | 25 | 30 | 40 | 55 |

| File | Language | Size |

|---|---|---|

Mixproof butterfly valve catalogue Mixproof butterfly valve catalogue |

English | 16.56MB |

Sanitary valves catalogue Sanitary valves catalogue |

English | 30.2MB |