Size:1"-4",DN6-DN100

Material:SS316L/1.4404,ASME BPE 316L,1.4435 NB2 Fe≤0.5%

Pressure:Vacuum to 10 bar (1.0 Mpa)

Max temperature:180℃, it depends on diaphragm material

Diaphragm:EPDM.,SILICON,FKM,FFKM,HNBR,NBR,EPDM+PTFE

Connection standard:DIN ,SMS,ISO,IDF,RJT,BPE,3A,DIN 11864,DIN11853

Connection way:threaded, clamp,welding,flange

Drive mode:manual,pneumatic,electronic

Roughness:Ra≤0.6um (default), Ra≤0.38um

Certification::US-3A-18-03,FDA 177.2600,CE

Sanitary aseptic BPE stainless steel pharmaceutical diaphragm valve

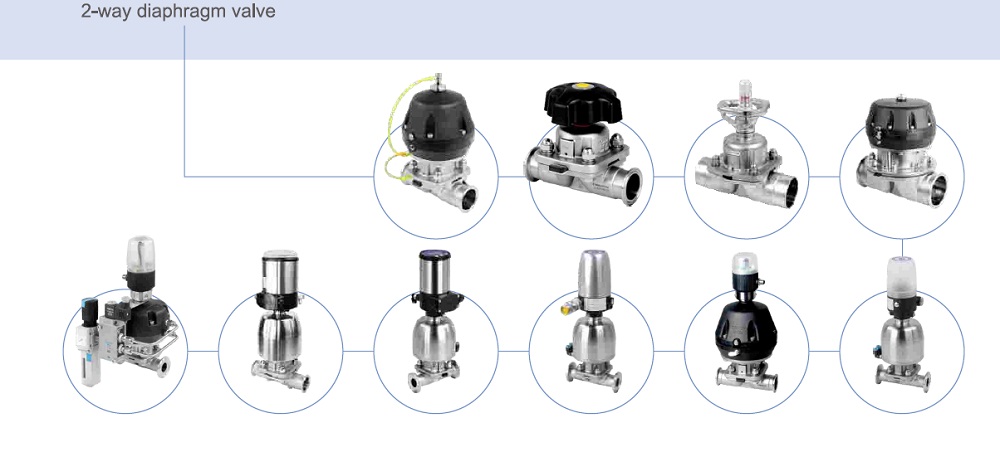

Donjoy has been manufacturing high-cleanliness diaphragm valves for 20 years and has applied more than 500,000 pieces in various fields, involving more than 300 varieties, such as 2-way, 3-way, U-shaped 3-way, multi-ports, adjustable, manual, pneumatic, electric, etc. And they are interchangeable.

Certification

Sanitary diaphram valves technical Features

Temperature: -20℃ to +150℃, Depending on the seal material

Connection standard: DIN SMS ISO IDF RJT BS4825 ASME BPE 3A DIN11864 DIN11853

Certification: FDA 177.2600; 3A-18-03; Glass II USP Glass VI Chapter 88; GB4806.11; EG VO/1935-2004; PED/97/23/EC.

Diaphragm choose

1. One piece diaphragm EPDM+PTFE (Max temperature 120℃)

PTFE diaphragm tablet has high chemical resistancemhigh stability,goof flexiblity.long life,high sealing,no cold degeneration,and not affected by temperature fluctuations excellent performance,whether it is thermal cycle,cold cycle,or steam disinfection system.

2. Single diaphragm EPDM/Silicon/FPM (Max temperature 120℃)

Rubber diaphragm embedded a layer of vulcanized fiber layer enhance its mechanical properties,teh diaphragm in pressure and temperature has high seal stbility.reinforcingfiber hardening in stainless steel bolt,as as to ensure better rubber and metal bond together,

Therefore rubber diaphragm more suitable for use in vacuum environment.

3. 2PC diaphragm EPDM+PTFE (Max temperature 150℃)

By EPDM and PTFE composed of diaphragm,the characteristics of the diaphragm is the valve is in the closed position,diaphragm itself shape can and body sealing,which reduces the diaphragm tolerance adn prolong the service life of the diaphragm.

Aseptic diaphragm valve application

Sanitary diaphragm valve,manual or pneuamtic operated, and specially designed for use on hygiene and aseptic processes in the pharmaceutical industries.

The valve is excellent for flow control as well as for open/close duties.

The diaphragm valve are better in feature of flow in comparison with other valves.It is easy to clean up and better to process the substance with particles.The phenomenon of air pocket is rare during application of flow control.

Sanitary diaphragm valve operating principles

The diaphragm provides the body seal as well as seat seal.There are no paths to the outside environment,so it is suitable for aseptic processes.

When the valve is closed a pressure pad which supports the diaphragm moves towards the sealing face on the body.When the pressure plate moves the diaphragm flexes and is forced down onto the seat area in the centre of the body thus closing off the flow path through the body.

The inter relationship of body to the pressure plate prevents over compression of the diaphragm.

The valve can be manual operation and pneumatic operation control tops of solenoid valve.

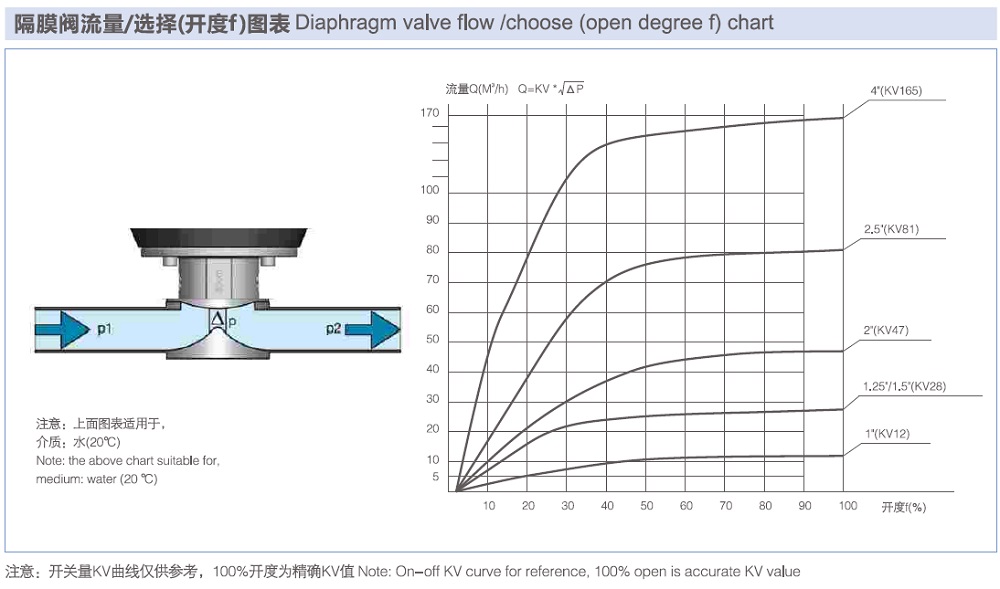

Sanitary diaphragm valve flow rate diapram

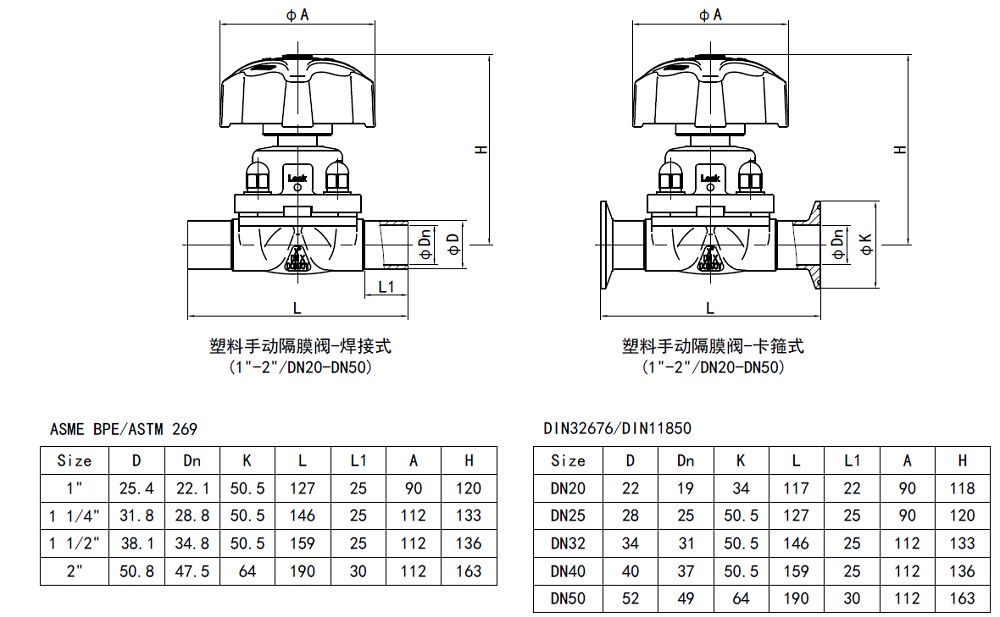

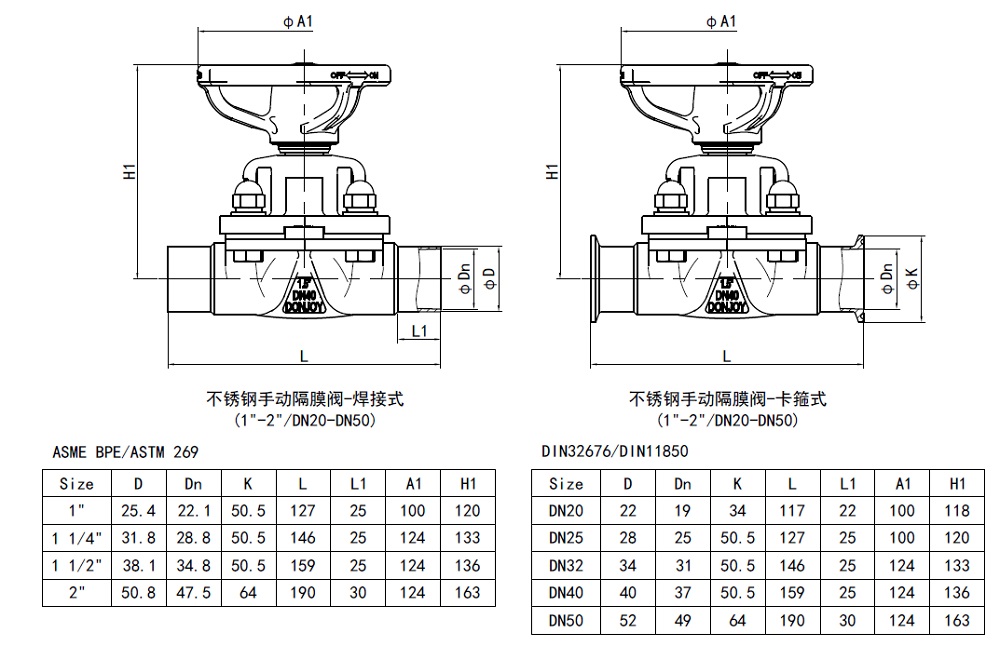

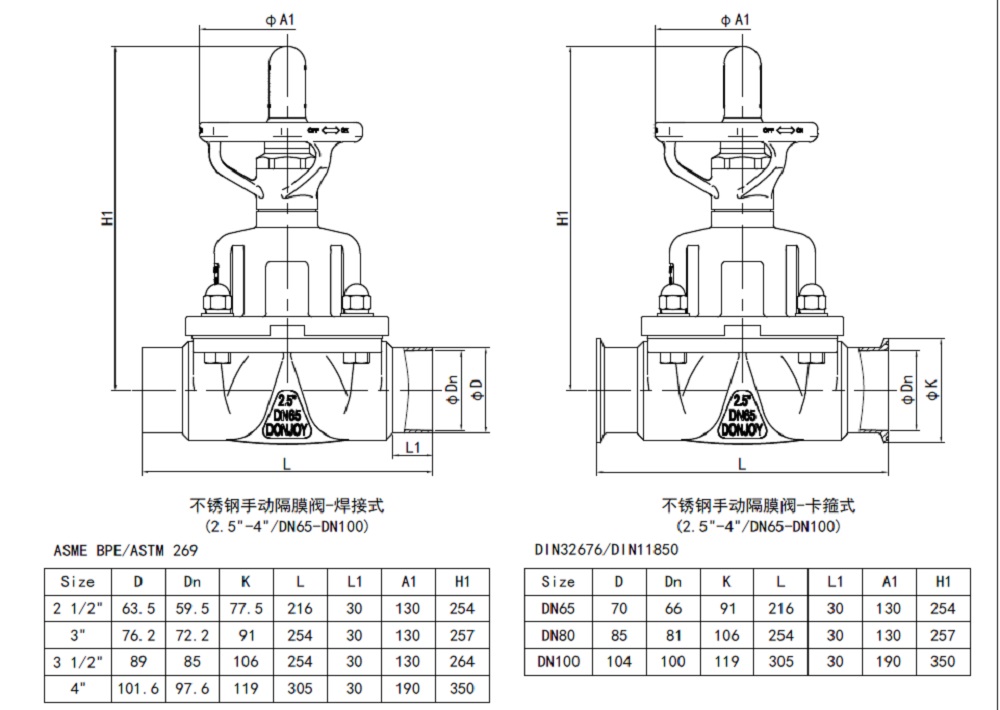

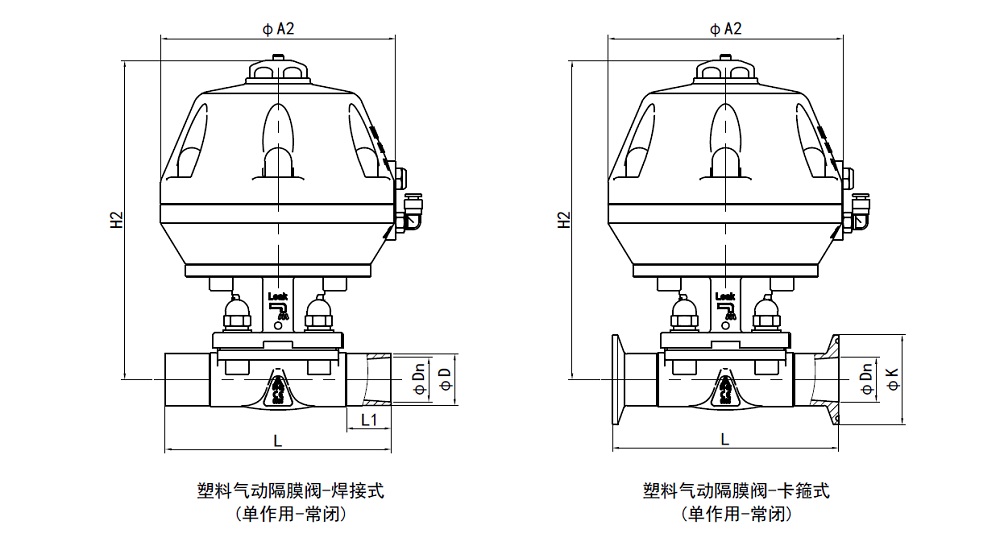

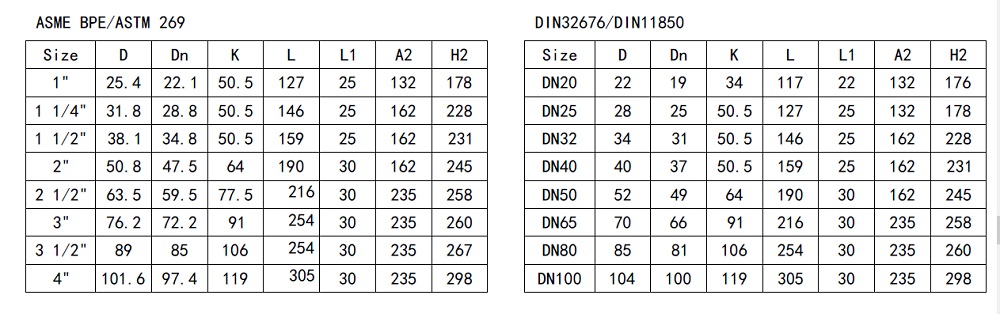

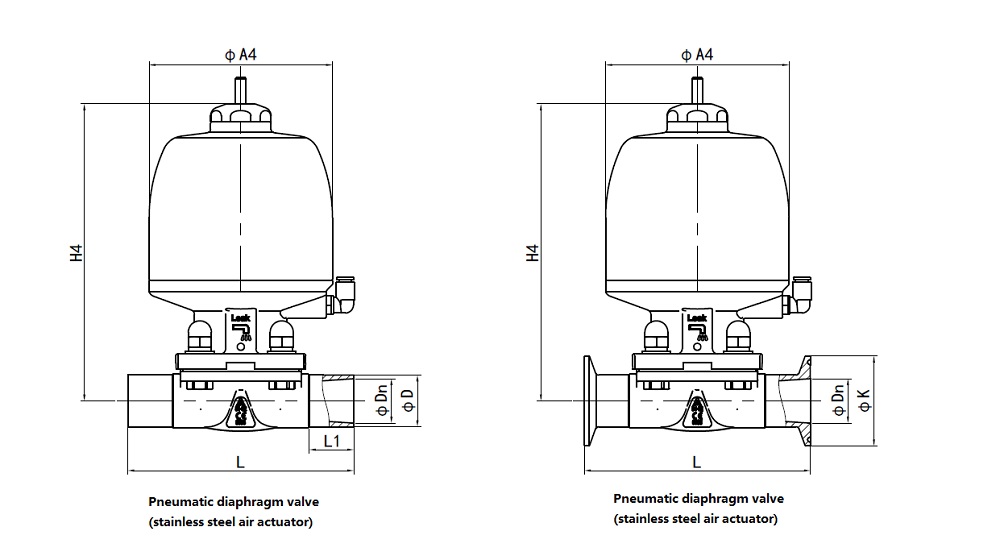

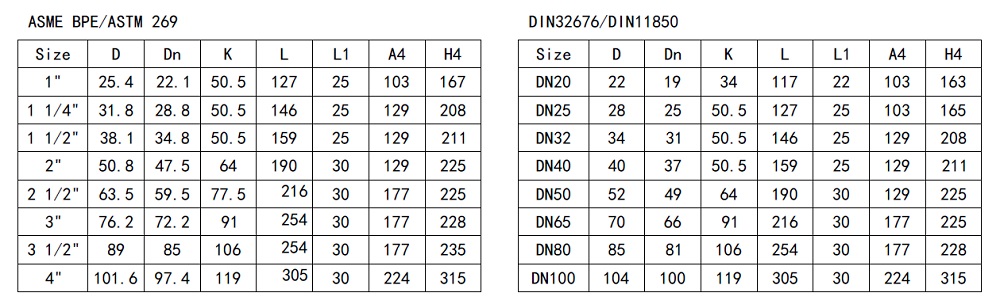

Sanitary Diaphragm valve drawing

Sanitary Diaphragm valve drawing

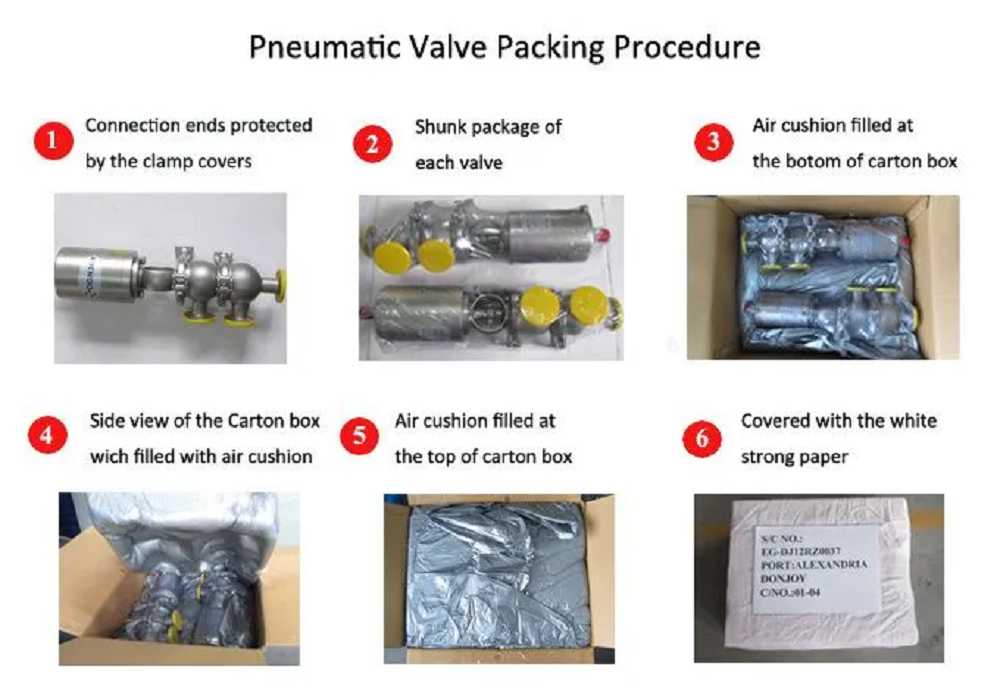

Pharmaceutical diaphragm valve package

Pharmaceutical diaphragm valve package

| File | Language | Size |

|---|---|---|

Diaphragm valve catalogue(newest) Diaphragm valve catalogue(newest) |

English | 18.63MB |

Diaphragm valve catalogue(old version) Diaphragm valve catalogue(old version) |

English | 7.16MB |

Sanitary valve catalogue Sanitary valve catalogue |

English | 30.2MB |