Specifications: 1/2"-6", DN10-DN150

Material: 316L/1.4404, ASME BPE 316L 1.4435 NB2 Fe≤0.5%

Pressure: Vacuum to 10bar (1.0 Mpa)

Seal: EPDM FKM HNBR PTFE

Connection method: Thread, clamp, welding, flange

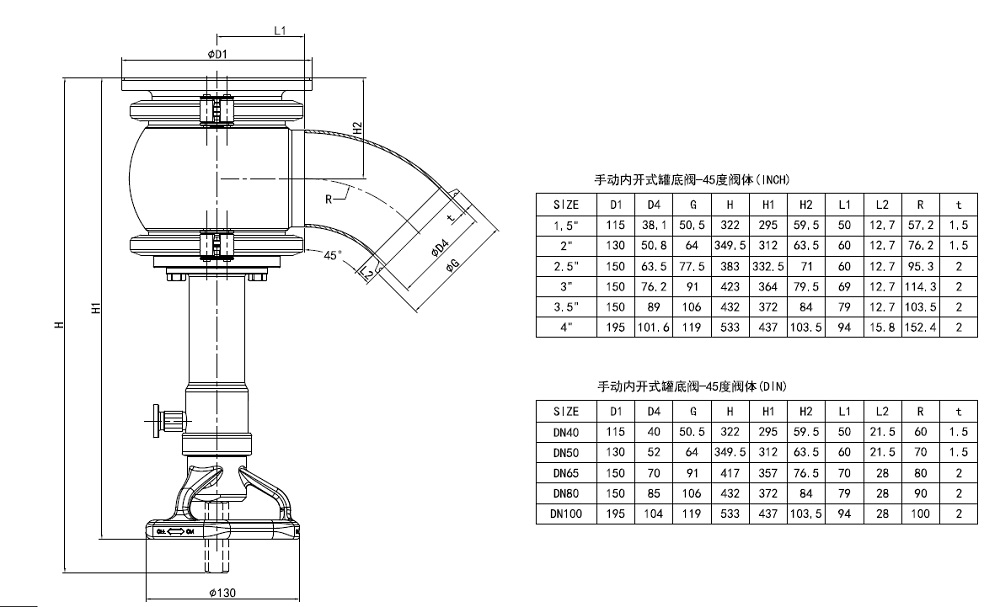

Drive mode: manual, pneumatic, electric

Finish: Ra≤0.6μm; MP=Ra≤0.3μm; EP=Ra≤0.3μm

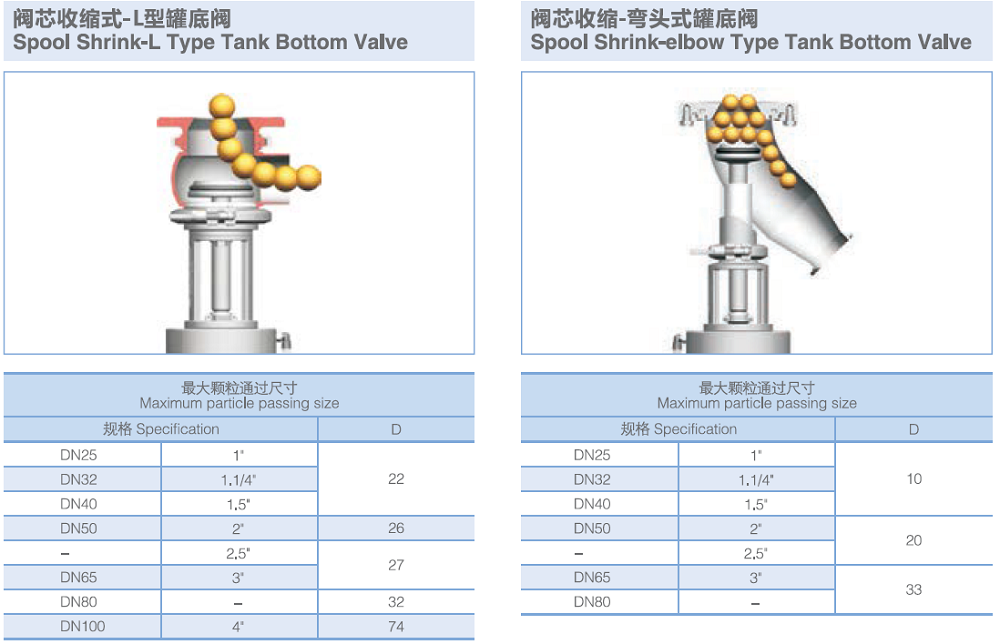

Sanitary flush tank bottom seat valve manufacturers(valve spool retractable)

The tank bottom valve has two designs of valve core contraction and valve core extension, and has a very flexible valve body combination and various functional configurations, such as sterilization type, jacket insulation, damping buffer type, etc. Various automatic controls such as valve positioners, control units, feedback devices, and position sensors can also be installed.

Valve spool extension: the valve stem opens toward the outside of the valve body and the valve stem moves upward. Can be singel acting and double acting

Valve spool retractable: the valve stem opens toward the inside of the valve body and the valve core moves downward. Only double acting,can't do single acting

Technical Features

Temperature: -20℃ to +150℃, Depending on the seal material

Connection standard: DIN SMS ISO IDF RJT BS4825 ASME BPE 3A DIN11864 DIN11853

Certification: FDA 177.2600; 3A-53-06; Glass II USP Glass VI Chapter 88; GB4806.11; EG VO/1935-2004; PED/97/23/EC.

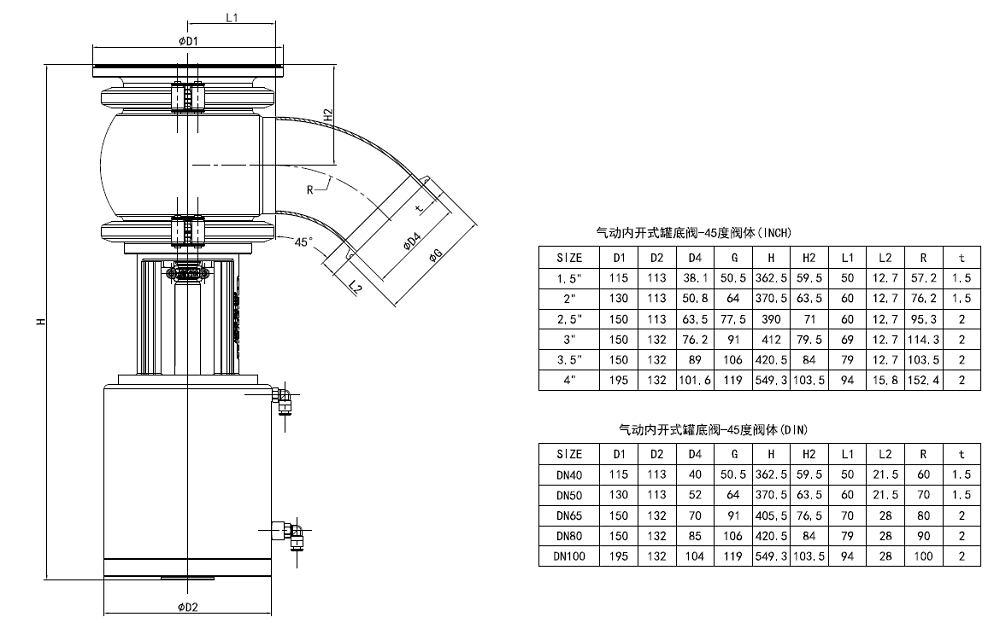

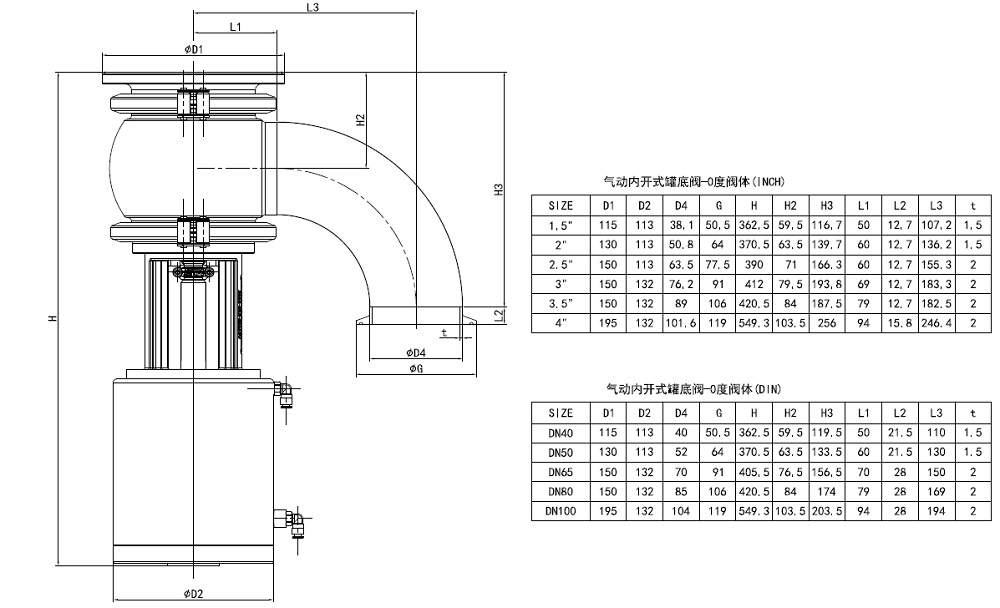

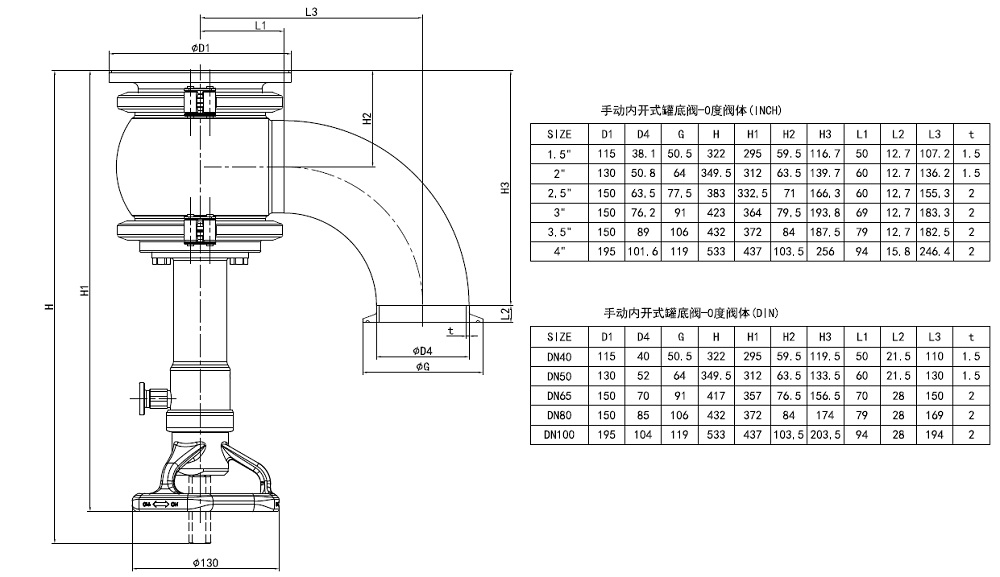

Sanitary tank bottom valve drawing

| File | Language | Size |

|---|---|---|

Tank bottom valve catalogue Tank bottom valve catalogue |

English | 16.82MB |

Single seat valve catalogue Single seat valve catalogue |

English | 6.93MB |

Sanitary valves catalogue Sanitary valves catalogue |

English | 30.2MB |