Specifications: 100mm-800mm

Material: 304/1.4301, 316L/1.4404, ASME BPE 316L 1.4435 NB2 Fe≤0.5%

Pressure: vacuum to 10bar (1.0 MPa)

Temperature: -20℃ to +150℃, Depending on the seal material

Sealing: EPDM FKM HNBR PTFE

Finish: Ra≤0.8μm; MP=Ra≤0.6μm; EP=Ra≤0.3μm

Certification: FDA 177.2600; 3A-84-02; Glass II USP Glass VI Chapter 88; GB4806.11; EG VO/1935-2004; PED/97/23/EC;

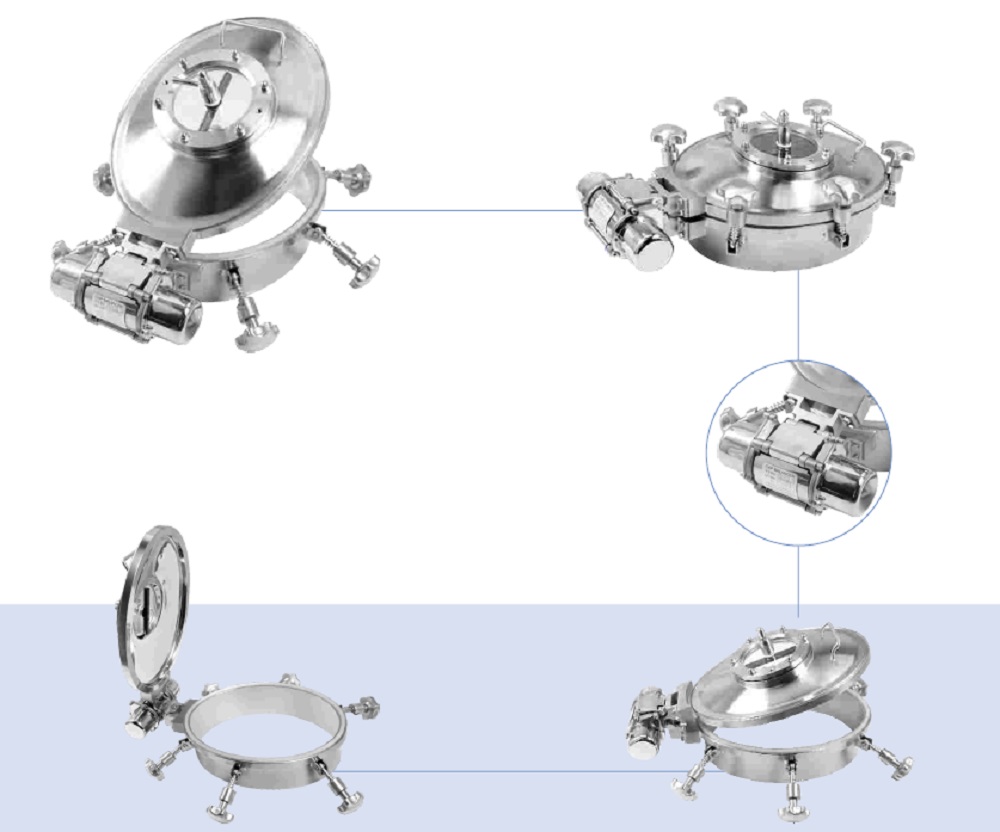

Hygienic stainless steel 304/316L round manhole cover with stainless steel handle,sight glass and damping system,when open and close the manhole cover,the speed is adjustable.

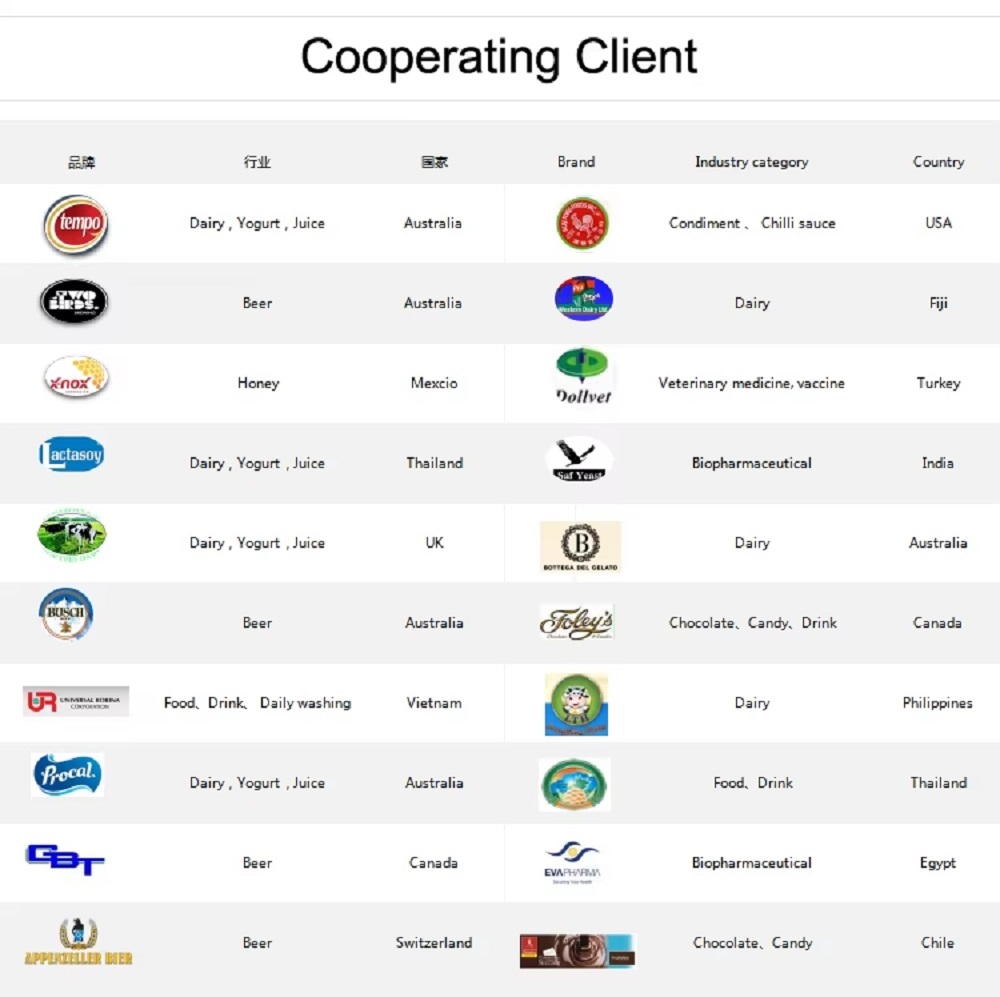

Application:

Food grade tank manholes are specialized access openings designed for containers,storage tanks,reactors in the food ,beverage,pharmaceutical,and cosmetics industries.

1.Food & Beverage Industry

2.Pharmaceutical & Biotech

3.Cosmetics & Chemicals

Working princples:

1.Seal design

-Uses food-grade gaskets (silicone, EPDM, or Viton/FPM) to prevent contamination from dust, microbes, or external pollutants.

2.Hygienic design

- Smooth internal surface (Ra ≤ 0.8 μm, per GMP standards) to prevent material buildup and allow easy CIP (Clean-in-Place) or SIP (Sterilize-in-Place).

- Made of 304/316L stainless steel for corrosion resistance and food compatibility.

3.Safety Features

- Pressure balance valves prevent sudden pressure release when opening.

- Explosion-proof versions may include rupture discs for overpressure protection

Hygienic tank manway function:

1.Hygiene Maintenance

- Prevents cross-contamination, ensuring compliance with food safety regulations (e.g., HACCP).

2.Operational Access

- Allows personnel entry for cleaning, inspection, or maintenance (large tanks must follow OSHA confined space regulations).

3.Material Handling

- Serves as a temporary filling port, sampling point, or connection for piping/pumping systems.

4.Safety Control

- Includes sight glasses or venting ports to monitor tank conditions and prevent vacuum/pressure hazards.

Specification:

Specifications: 100mm-800mm

Material: 304/1.4301, 316L/1.4404, ASME BPE 316L 1.4435 NB2 Fe≤0.5%

Pressure: vacuum to 10bar (1.0 MPa)

Temperature: -20℃ to +150℃, Depending on the seal material

Sealing: EPDM FKM HNBR PTFE

Finish: Ra≤0.8μm; MP=Ra≤0.6μm; EP=Ra≤0.3μm

Certification: FDA 177.2600; 3A-84-02; Glass II USP Glass VI Chapter 88; GB4806.11; EG VO/1935-2004; PED/97/23/EC;

| File | Language | Size |

|---|---|---|

Manhole cover catalogue Manhole cover catalogue |

English | 15.26MB |

Sanitary valves catalogue Sanitary valves catalogue |

English | 30.2MB |