Donjoy factory building in 1993 year,located in Wenzhou,China

DONJOY Hygienic stainless steel low shear sine pump PZX for food processings

Sine pump is a new type of positive displacement pump, which has the characteristics of more compact structure, higher conveying efficiency, and wider viscosity range of applicable conveying medium. Can be widely used in food, beverage, dairy, chemical, pharmaceutical and other industries.

Sine pump application:

Sine pumps can be used in industries such as food, beverages, dairy products, biopharmaceuticals, daily chemicals and fine chemicals.

PZX series sine pumps can transfer products containing soft solid ingredients, such as soups, beverages, cheese, butter, shampoo, detergents and other products.

Lobe pumps, twin screw pumps and sine pumps can all be used for viscous liquids, and their application ranges are similar, but sine pumps and screw pumps are both used for particulate media, while lobe pumps cannot. Compared with twin screw pumps, sine pumps are more suitable for high-precision, low-shear occasions such as pharmaceutical and fine cosmetics industries, such as injections, high-value-added liquid medicines, high-precision emulsions, etc.

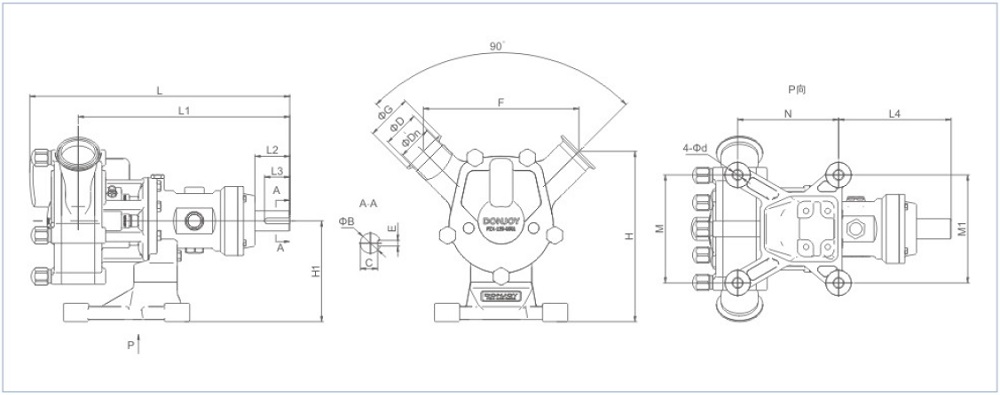

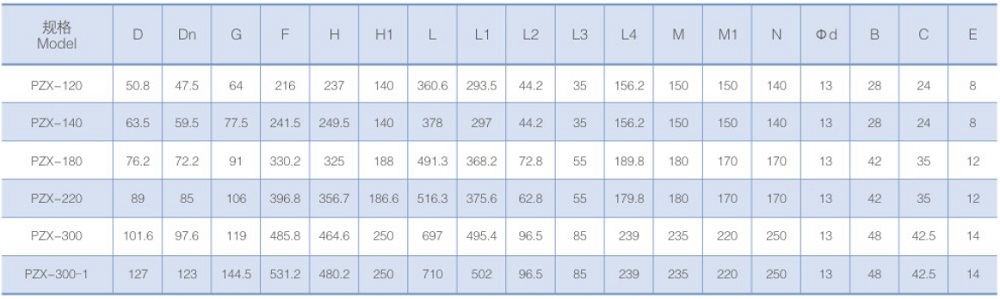

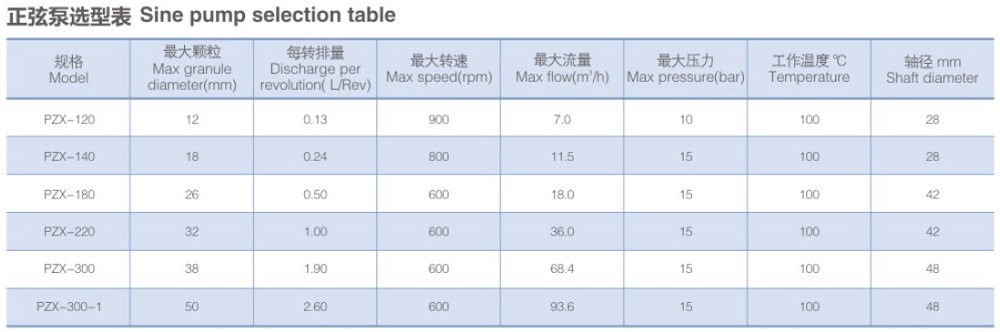

Masosine pump model table

Masosine pump model table

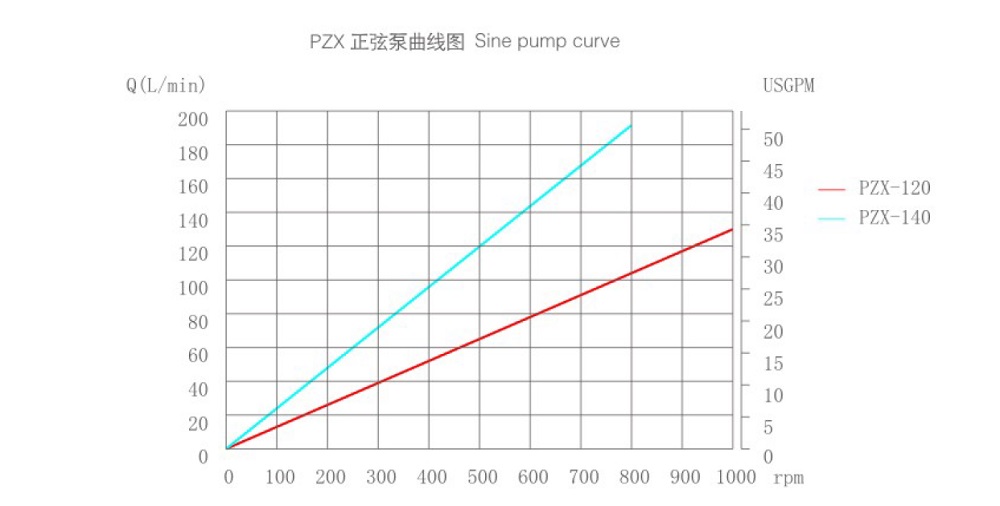

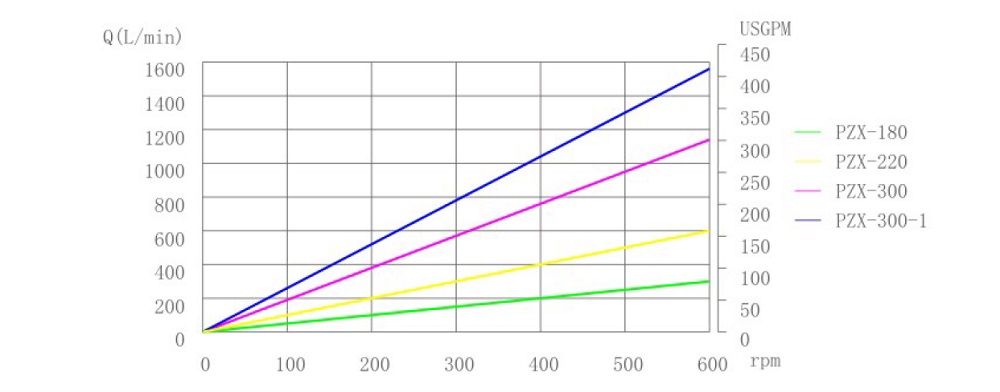

Masosine pump performance curve

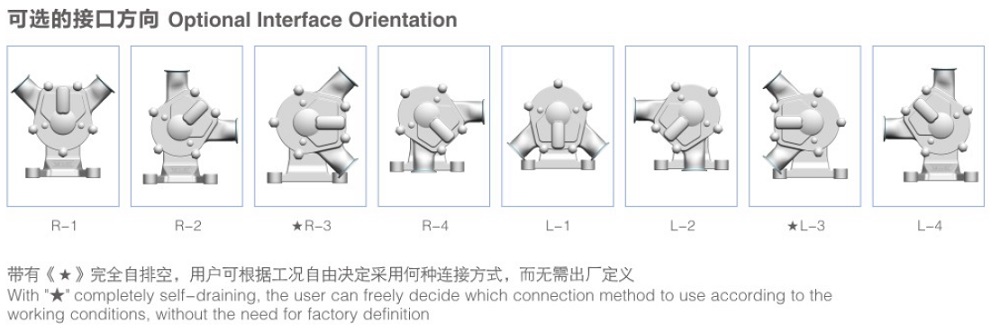

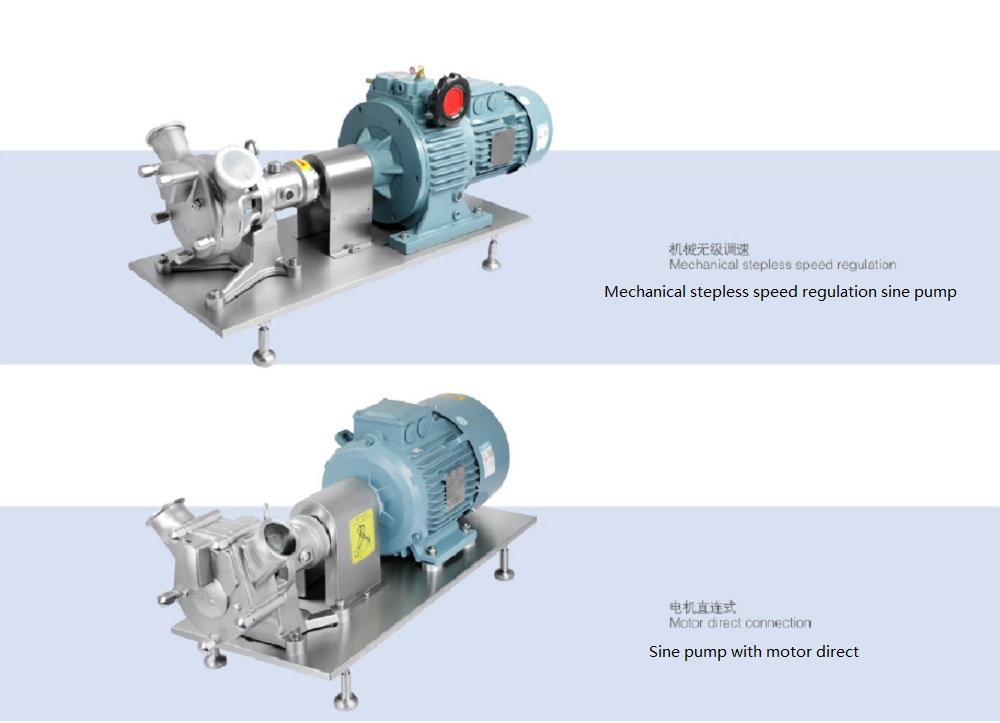

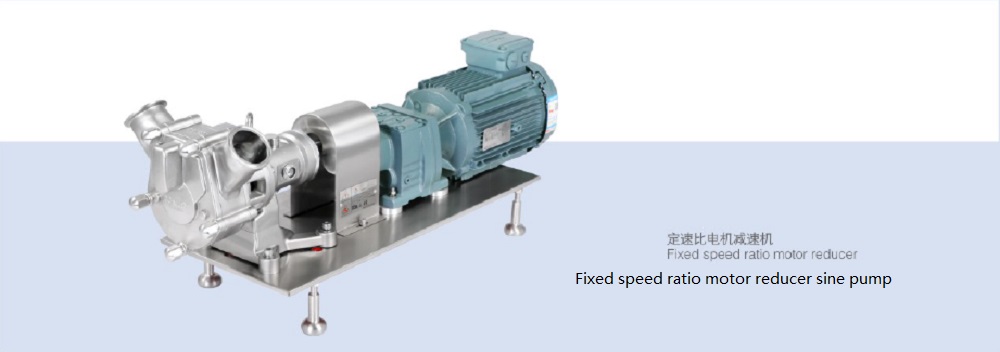

Various sine pump configuration

Sine pump is a new type of positive displacement pump, which has the characteristics of more compact structure, higher conveying efficiency, and wider viscosity range of applicable conveying medium. Can be widely used in food, beverage, dairy, chemical, pharmaceutical and other industries.

Bidirectional reversible operation, worry-free granule transferring,no damage to material transferring, worry-free high and low viscosity,super self-priming ability, no pulse in transferring, clean, efficient,durable, safe, and low-cost solutions

Technical advantages

●Ultra-low shear conveying to effectively ensure media integrity

●High suction capacity, inlet negative pressure can reach -0.85bar

●Low-pulse conveying can effectively prevent pipeline vibration, make the medium convey smoothly and quickly, and also increase the measurement accuracy

●The conveying process is gentle, and it is not easy to generate air bubbles

●Bidirectional operation

●Simple and fast maintenance

●All medium contacting parts comply with FDA and EC1935 standards

●Wide range of medium viscosity, 1cp to 8,000,000cps

| File | Language | Size |

|---|---|---|

Sanitary pump catalogue Sanitary pump catalogue |

English | 27.54MB |