Max flow rate: 60m3/h

Pump head material:SS316L, dual phase steel 2205, hastellot alloy C276

Max pressure:15 bar

Max revolution:750RPM

Surface finish:≤0.8um

Certificaiton:3-A-02-12 NO.1759, FDA 177.2600,CE-MD/04-42 NO.705201402101-00

Max temperature:150℃

Package:Wooden box

DONJOY food grade sanitary rotary lobe pump SS316L

Flexible solution for two-direction reversible, high viscosity,low viscosity, all stainless steel, low pulse, liquid transportation

Lobe pump vs gear pump

Lobe Pump:

lobe pump is a type of rotary positive displacement pump that has two meshing lobes that rotate in opposite directions. The lobe pump is also known as a rotary lobe pump or a twin lobe pump. This pump is used for pumping different types of viscous and non-viscous fluids. Lobe pumps are also well-suited for handling abrasive and shear-sensitive fluids.

Advantages:

- High volumetric efficiency

- Able to handle viscous fluids

- Low shear forces

- Minimal pulsation and turbulence

- High flow rates

- Easy to maintain

Disadvantages:

- Expensive to purchase

- Requires detailed installation and maintenance

- Lobe pumps can be noisy

- Heavy and bulky

- Limited to certain applications and environments

Gear Pump:

gear pump is a positive displacement pump that uses a set of rotating gears to transfer fluids. This type of pump can handle a wide range of viscosities and fluid types, including liquids with low lubricity. It mainly used for the liquids with solid particles,like juice with chunks.

Advantages:

- Smooth and steady flow of liquid

- Compact and lightweight

- Wide viscosity range

- Relatively inexpensive

- Easy to install and operate

- Can handle high pressure applications

Disadvantages:

- Higher shear forces and turbulence

- Sensitive to fluid contamination

- Requires more maintenance than other types of pumps

- Noisier compared to some pumps

In summary, lobe pumps provide high volumetric efficiency, low shear forces, and easier maintenance; while gear pumps offer a smooth and steady flow of liquid, compact design, and ability to handle a wide range of viscosities at an affordable price. Each type of pump has its strengths and weaknesses, and the right selection depends on the specific application requirements.

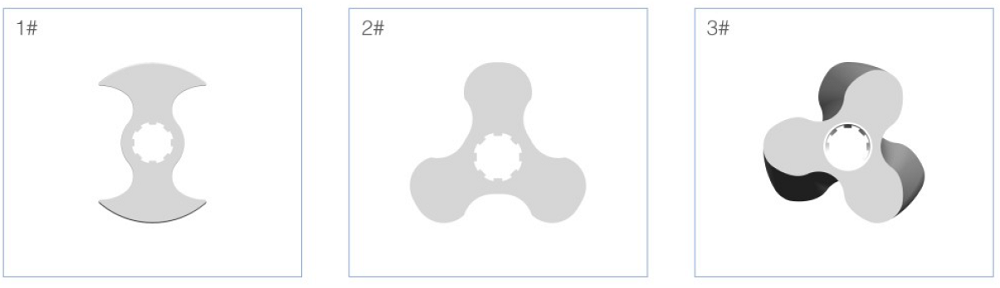

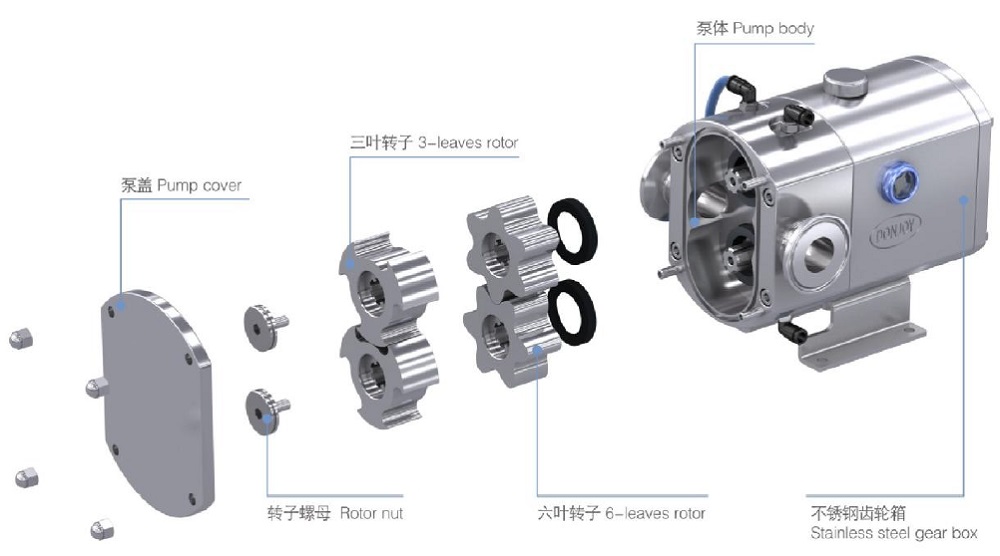

Different lobe for rotary lobe pump

Butterfly valve (standard) 3 leaves rotor (standard) Sprial 3 leaves rotor (optional)

With lower particles breakage rate and small With granules breakage rate and smaller pulse With low granule breakage rate,very small pulse

Pulse,suitable for transporting material with granules than butterfly rotor,suitable for transporting and high cost,suitable for transporting all kinds

all kinds of material. of material.

Single butterfly rotor (optional) 2 leaves rotor (optional) 5 leaves rotor (optional)

With low granule breakage rate for large particle, With granule breakage rate,large pulse,low With high granule breakage rate,very small pulse

large pulse,low pressure and small volume, pressure and small volume,suitable for and smaller flow,suitable for transporting all kinds

suitable for transporting material with large transporting all kinds of material. of mateterial.

particle.

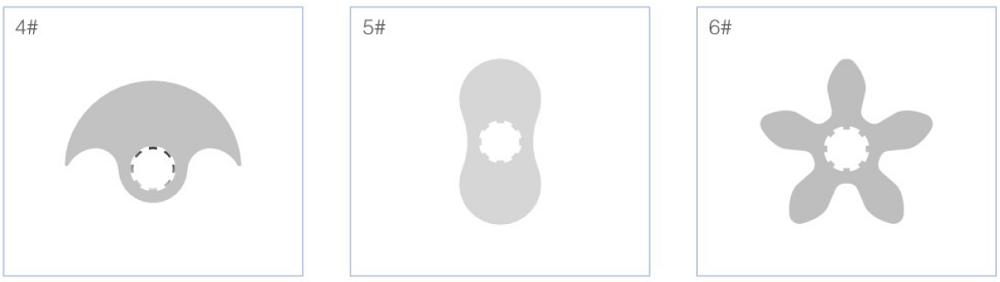

Bare rotary lobe pump selection table

| Model | Inlet and outlet size |

Max pressure (bar) |

Max rotate speed (RPM) |

Recommend rotate speed range(RPM) |

Flow per revolution (L/R) |

Max flow (m3/h) |

Flow rate range (m3/h) |

| TUL-20 or TUR-20 | 1"-DN25 | 15 | 700 | 100-500 | 0.12 | 5.1 | 0.7-3.6 |

| TUL-23 or TUR-23 | 1.5"-DN40 | 15 | 700 | 100-500 | 0.17 | 7.2 | 1.02-5.1 |

| TUL-25 or TUR-25 | 2"-DN50 | 15 | 700 | 100-500 | 0.24 | 10.1 | 1.43-5.7 |

| TUL-30 or TUR-30 | 2"-DN50 | 15 | 700 | 100-500 | 0.39 | 15.7 | 2.32-9.3 |

| TUL-35 or TUR-35 | 2.5" | 12 | 700 | 100-500 | 0.48 | 20 | 2.9-11.6 |

| TUL-55 or TUR-55 | DN65 | 12 | 500 | 100-400 | 0.55 | 16.5 | 3.3-13.2 |

| TUL-60 or TUR-60 | 3" | 10 | 500 | 100-400 | 0.61 | 18.3 | 3.64-14.6 |

| TUL-70 or TUR-70 | 3“ | 15 | 500 | 50-400 | 1.41 | 42.3 | 4.24-33.9 |

| TUL-80 or TUR-80 | DN80 | 15 | 500 | 50-400 | 1.41 | 42.3 | 4.24-33.9 |

| TUL-100 or TUR-100 | 4"-DN100 | 10 | 500 | 50-400 | 1.81 | 54.3 | 5.44-43.5 |

| TUL-125 or TUR-125 | 5"-DN125 | 10 | 500 | 50-400 | 2.3 | 69 | 6.91-55.3 |

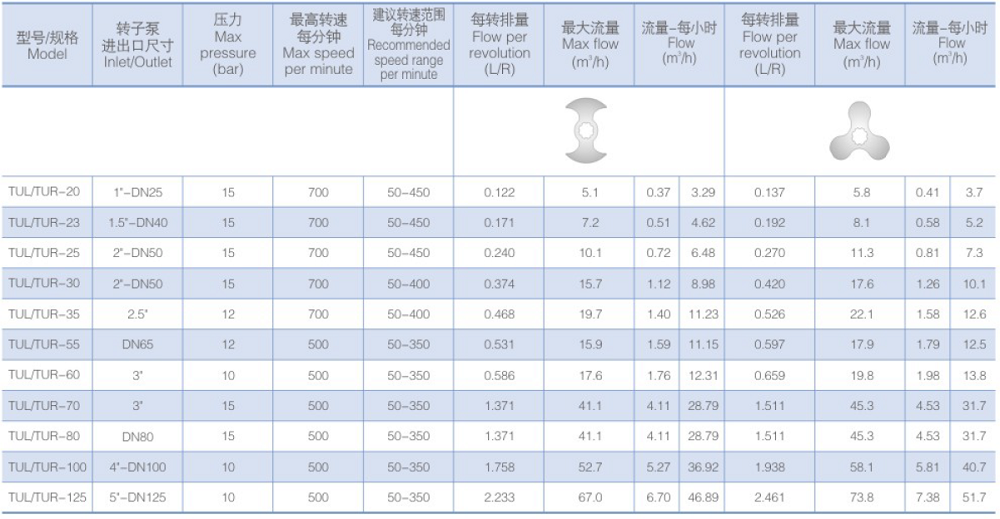

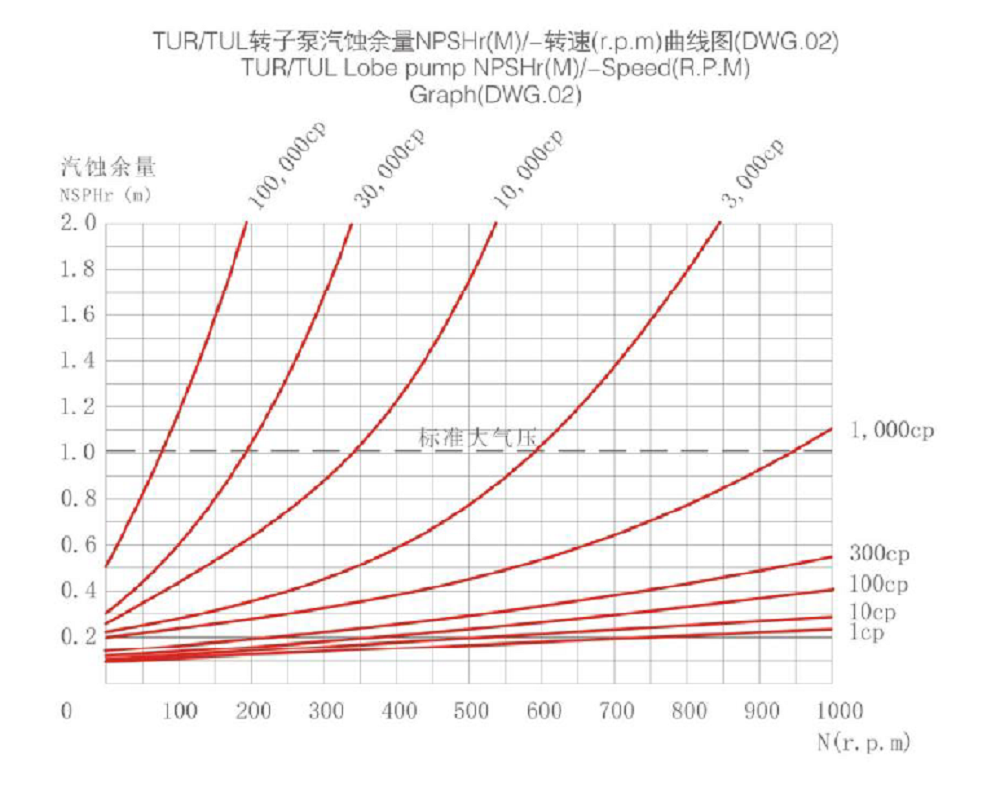

Rotary lobe pump performance curve

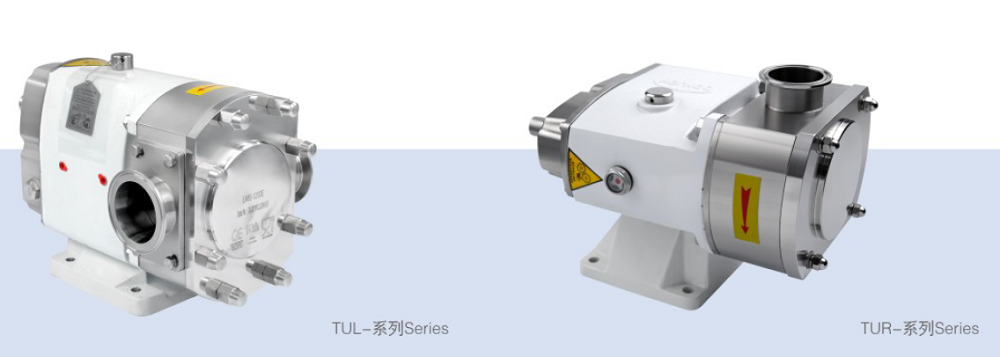

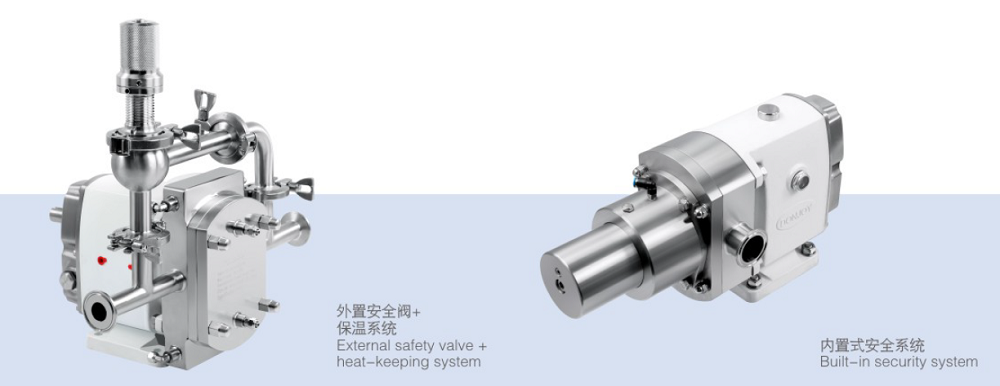

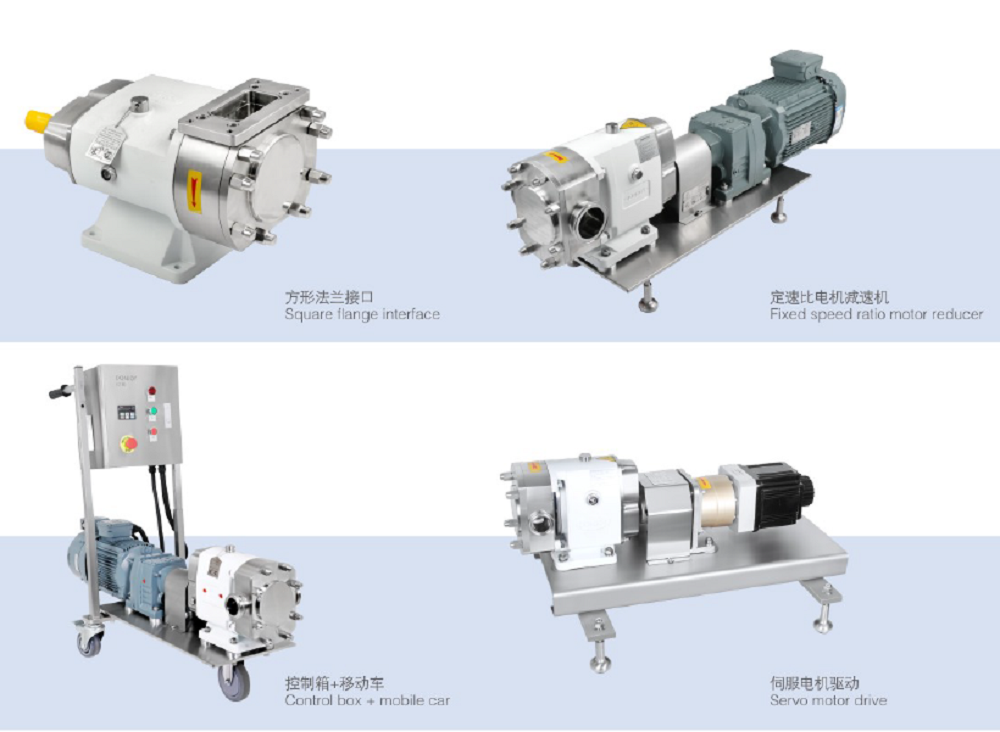

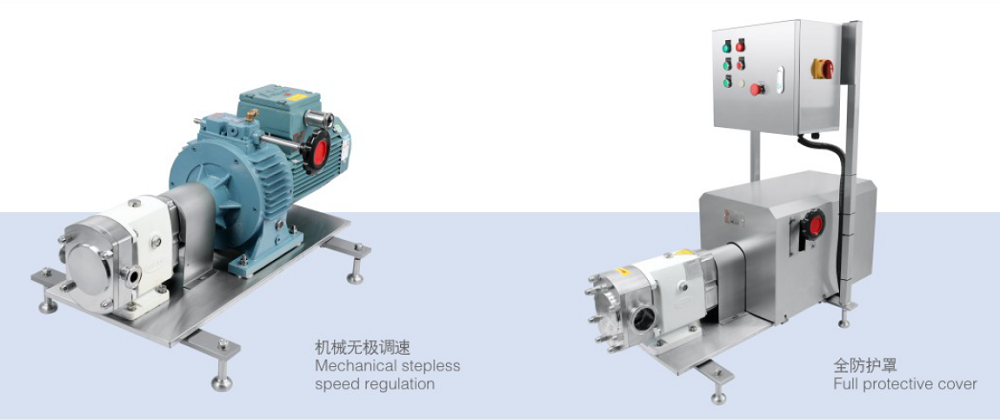

Various lobe pump configuration

The design of each pump is based on - US Sanitary Standard "3A-02-12", EU Safety Directive Design "MD/06/42/EC"

International leading partners - Siemens, ABB, SEW, WH, Roplan, to ensure that each pump is more durable, efficient, clean and safe

Solution for two-direction reversible,high pressure, high and low viscosity, solid,granule high clean solution

The design of each pump is based on -US Sanitary Standard "3A-02-12",EU Safety Directive Design "MD/06/42/EC"

International leading partners -Siemens, ABB, SEW, WH, Roplan,to ensure that each pump is more durable,efficient, clean and safe

| File | Language | Size |

|---|---|---|

Lobe pump catalogue Lobe pump catalogue |

English | 16.18MB |

DONJOY pump catalogue DONJOY pump catalogue |

English | 27.54MB |