Max flow rate :50m3/h

Max power:90KW

Working temperatire -20℃ to 150℃

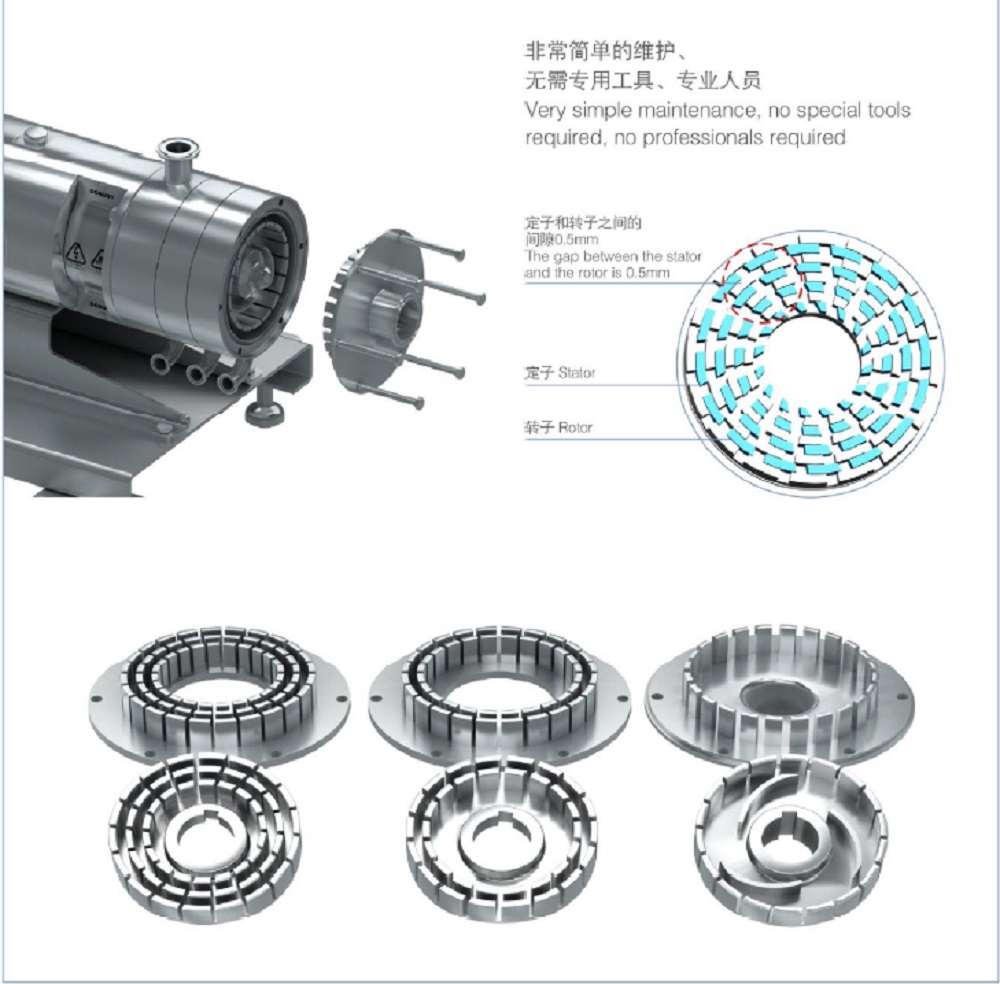

Media refinement:≤100 grit

Material:304/316L,1.431/1.4404,ASME BPE 316L,1.4435 NB2 Fe≤0.5%

Surface:Ra≤0.8im, ≤Ra 0.6um,≤Ra 0.4um,

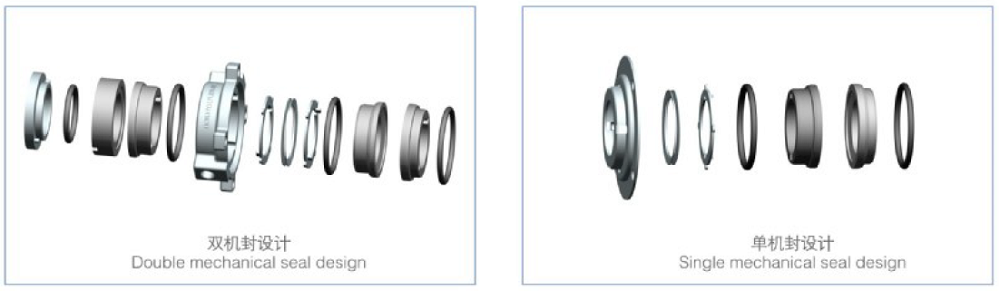

Mechanical seal:single mechanicall seal .double mechancial seal

Connection way,Clamp. thread, flange,aseptic flange

Donjoy factory building in 1993 year,located in Wenzhou,China

DONJOY sanitary stainless steel emulsifying homogenizing pump,inline homogenizer mixer pump

Solution for high-efficiency, dispersion, cut, refinement, smash,emulsification, mixing, homogenization, high purity

Final granule diameter after emulsifying and homogenizing: Final granule diameter (nM) depends on medium

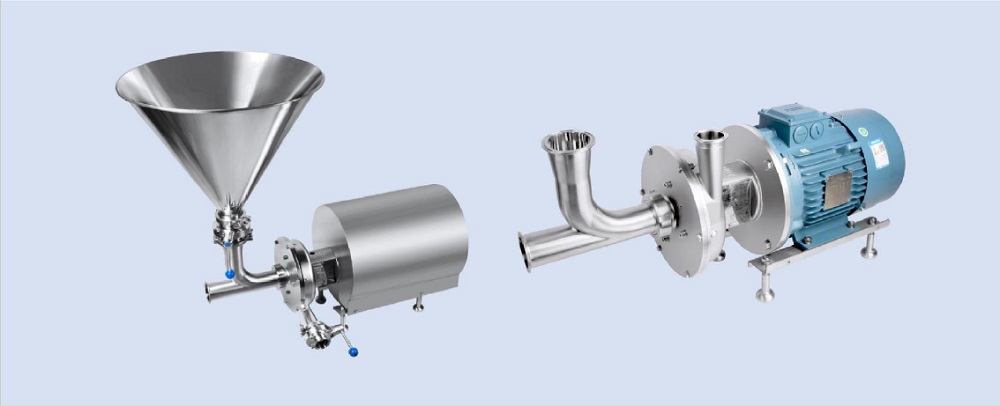

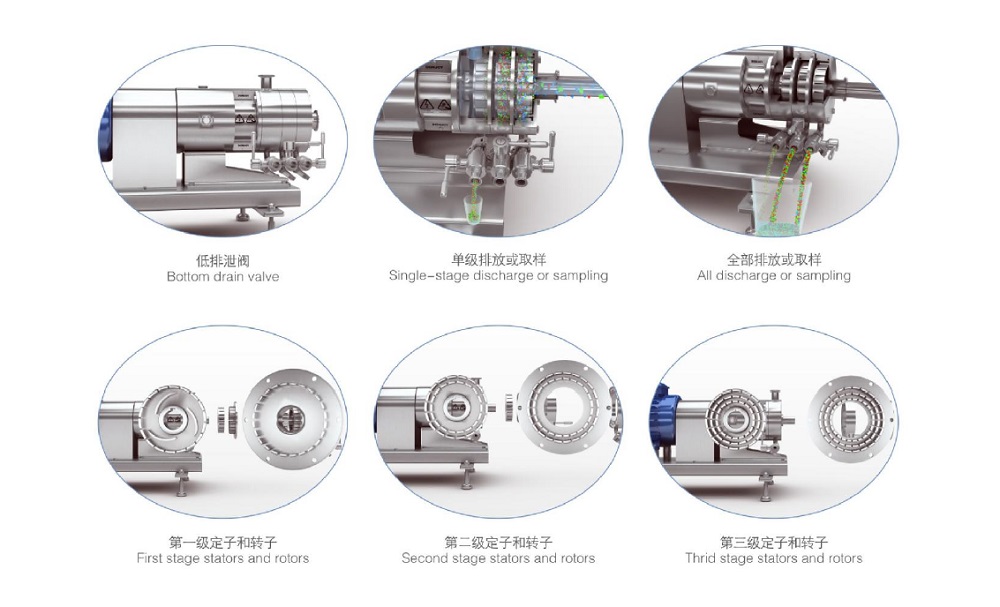

DONJOY homogenizing pump have two types: single stage homogenizer pump, and multi-stage homogenizer pump.

The max viscosity ≤7000cps

Single stage homogenizing pump

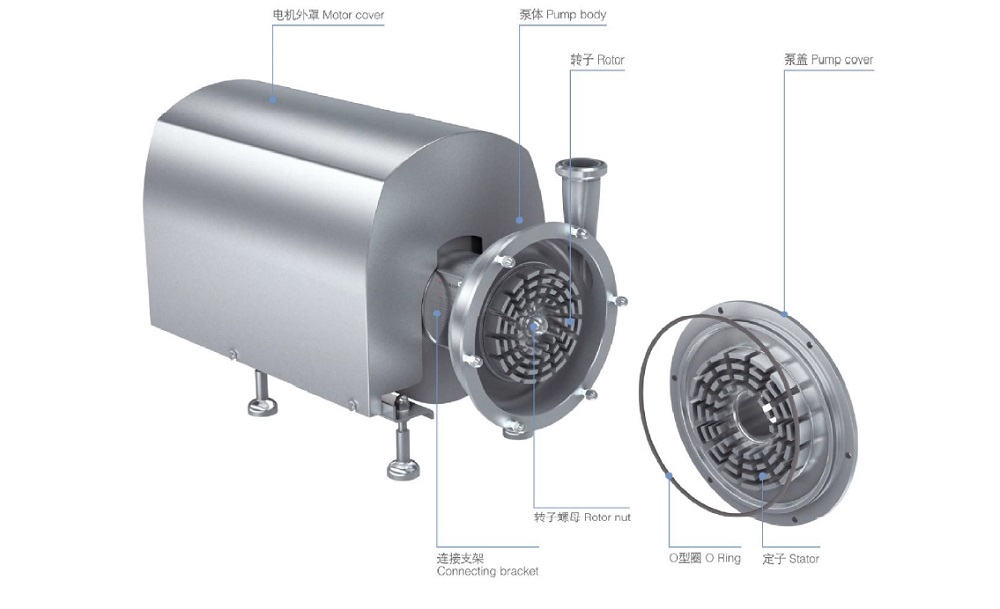

Single stage homogenizing working operation:

Single stage emulsifying homogenizing pump that could be operated for continuous production,and is composed of stator and rotor.The processed madia will be operated through 6-10 layers and rotors,and then be dispersed,cut,refied,smashed,emulsified,mixed etc, step by step.Compared with traditional manufacturing technique,this pump is more easier ,convenient and optimized,which has improved production effiency and promoted media quality.It's mainly used in the industry of food,beverage,pharmacy,health protection,fine,chemistry,coating,pesticide,daily chemical,papermarking,etc.

Technical advantage

Mechanical seal advantage

Emulsification homogenzing pump application:

We DONJOY have 2 types of emulsifying homogenizing pumps, single-stage JZ1 and multi-stage JZ2 and JZ3.

Emulsifying homogenizing pumps mainly shear and homogenize two miscible media to achieve material refinement, such as water and salt, liquid and powder. Material refinement ≤60 grit (around 300um).

Mainly used in various industrial fields such as food, beverage, pharmaceutical, health care, fine chemicals, coatings, pesticides, daily chemical washing, papermaking, etc.

Single-stage homogenizing pump JZ1, can be used for ≤7000cps

Multi-stage homogenizing pumps JZ2 and JZ3, can be used for ≤5000cps

Multi-stage homogenizing pump

Multi-stage homogenizing pump

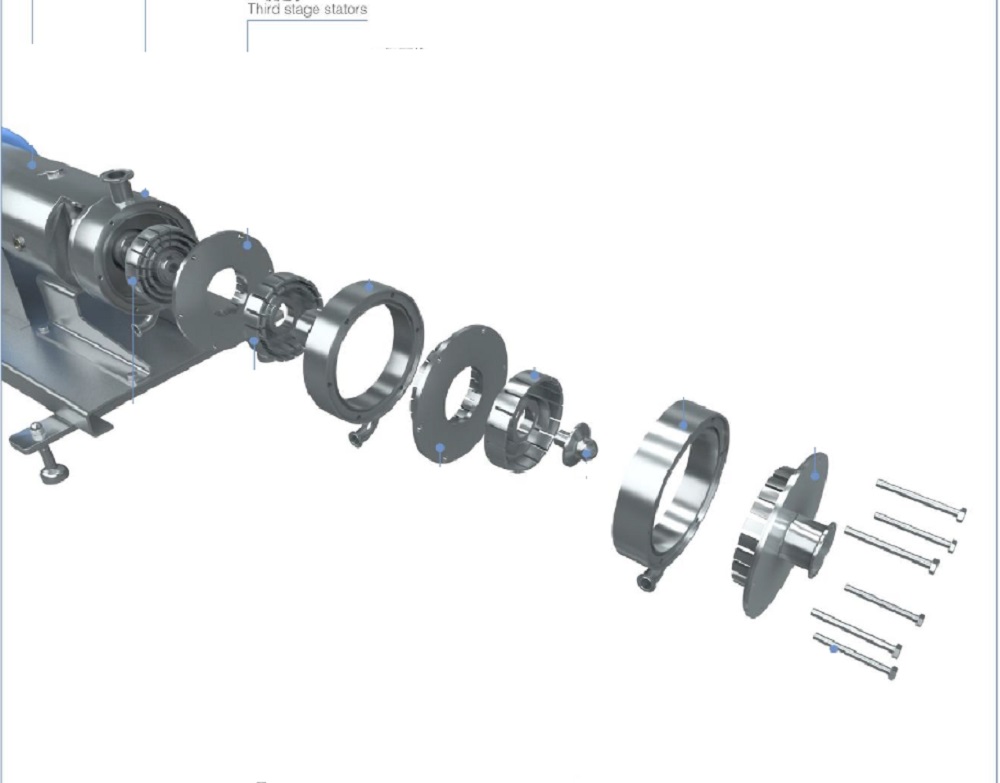

Multi-stage homogenizing pump working operation:

Multi-stage emulsifying homogenizing pump is online continuity production emulsification homogeneous pump, and is composed by stator and rotor.The processed materials will be stepwise dispersed,sheared,refined,crushed,emulsified,mixed and homogenized through three grades 12 stators and rotors,and then be dispersed,cut,refined,smashed,emulsified,mixed etc,step by sep.Compared with traditional manufacturing technique,this pump is more easier ,convenient and optimized,which has improved production effiency and promoted media quality.It's mainly used in the industry of food,beverage,pharmacy,health protection,fine,chemistry,coating,pesticide,daily chemical,papermarking,etc.

| File | Language | Size |

|---|---|---|

Emlusitying homogenizing pump catalogue Emlusitying homogenizing pump catalogue |

English | 5.65MB |

Sanitary pump catalogue Sanitary pump catalogue |

English | 27.54MB |