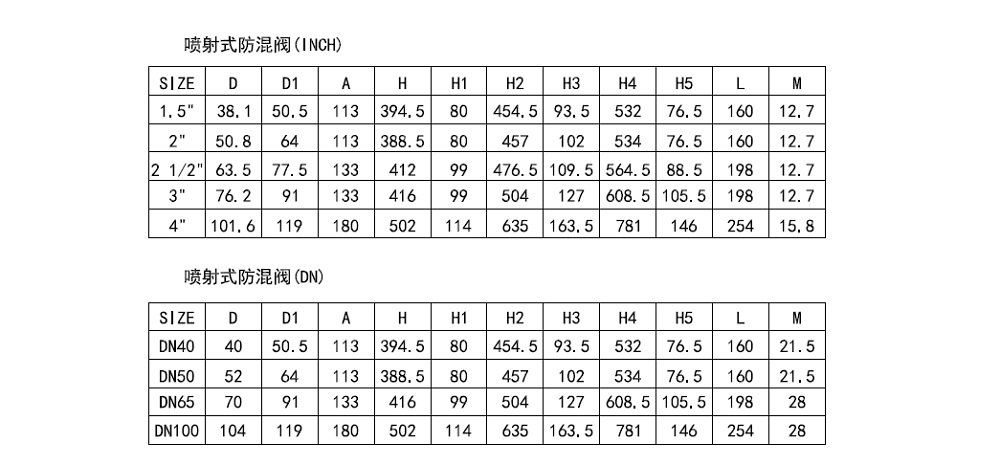

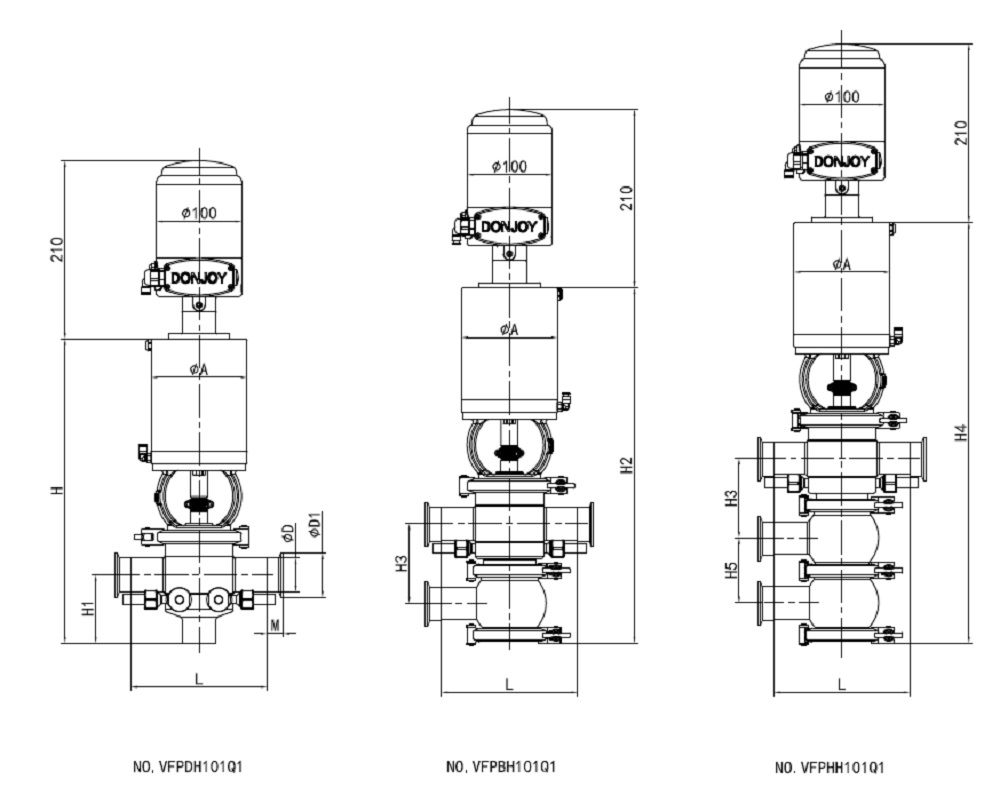

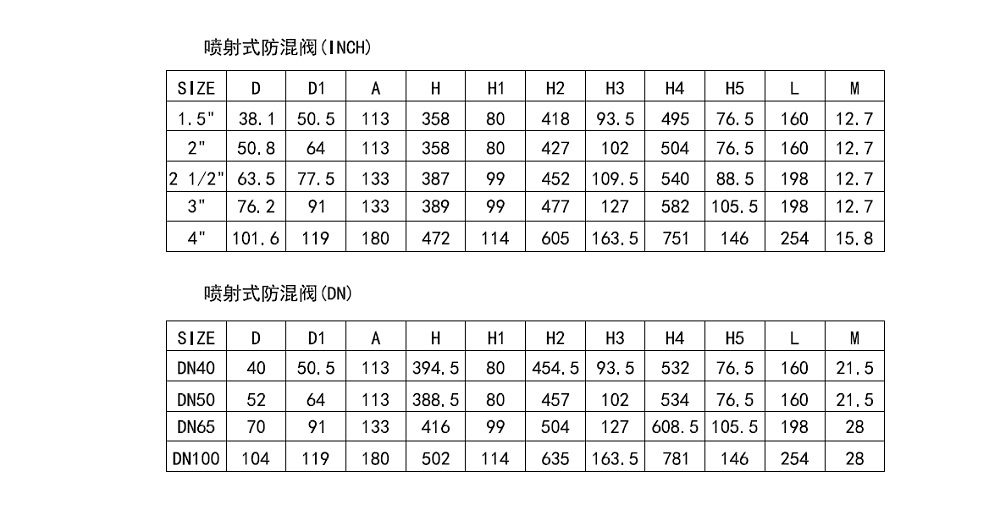

Size: 1.5"-4",DN40-DN100

Parts in contract with the media:AISI 316L

Other stainless steel parts:AISI 304

Internal surface finish:Ra≤0.8um

Gasket :EPDM in compliance with FDA 177.2600

Connection way:Welding or clamp ends

Maximum pressure:6 bar

Minimum pressure:Vacuum

Working temperature:-10°C to 120°C (150°C optional)

Air resource:5-7 bar

Air resource connection: thread G 1/8"

External surface finish:Matte (sandblasting)

Internal surface finish:Ra<0.8um

Optional

Gasket:NBR, or FPM(Viton)

Control box C-TOP: DC24V, AS-i BUS

Surface finish:Ra≤0.4um

Donjoy factory building in 1993 year,located in Wenzhou,China

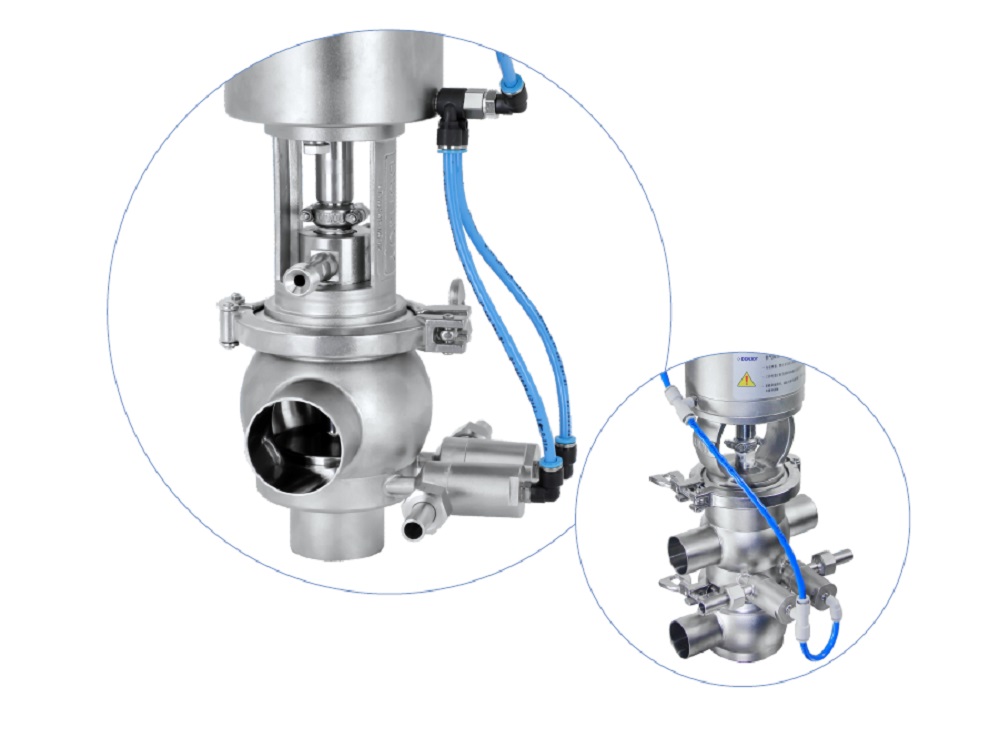

Sanitary stainless steel 316L hygienic CIP double seat mixproof valve

Applications

The external supply CIP mixing proof valve is designed to meet when there are two different liquids or products through the same valve,both guarantee to prevent fluid mixing and convenient for monitoring the working condition.

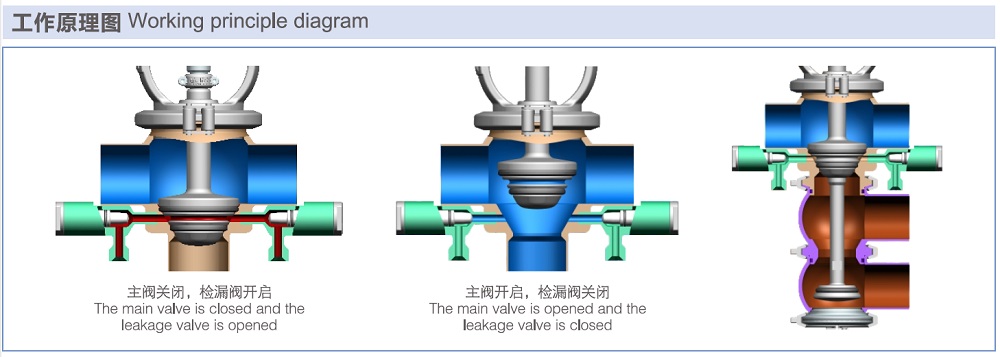

How do mixproof valve work?

Mixproof valves work by using a double-seat design to isolate two different fluids or products passing through the valve.

The valve position is controlled by an actuator with compressed air. The valve is normally closed under normal conditions. Double seat mixproof valve is companied with two small normally open pneumatic valves,one for monitoring,anther one for CIP.

The valve plug (upper stem inside of single seat valve) has two seals,which from a leakage chamber between each other,the leakage medium flow into the chamber,discharge through detector valve.Supply air to actuator can make the valve clean in place. Under cleaning.liquids flow directly to the plug,this valve is unsensitive to water hammer effect.

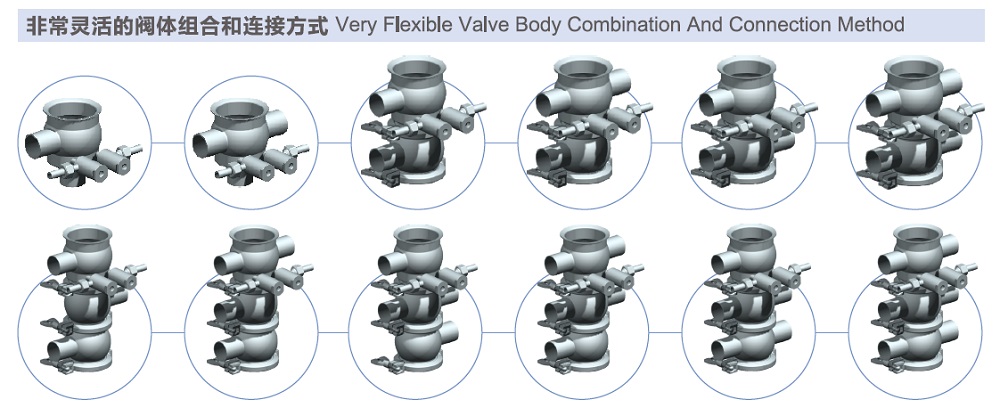

CIP double seat mixproof valve various body combination

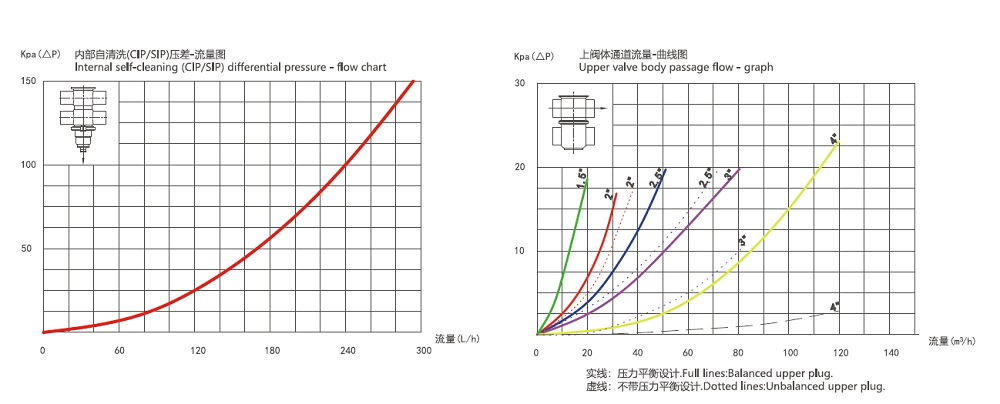

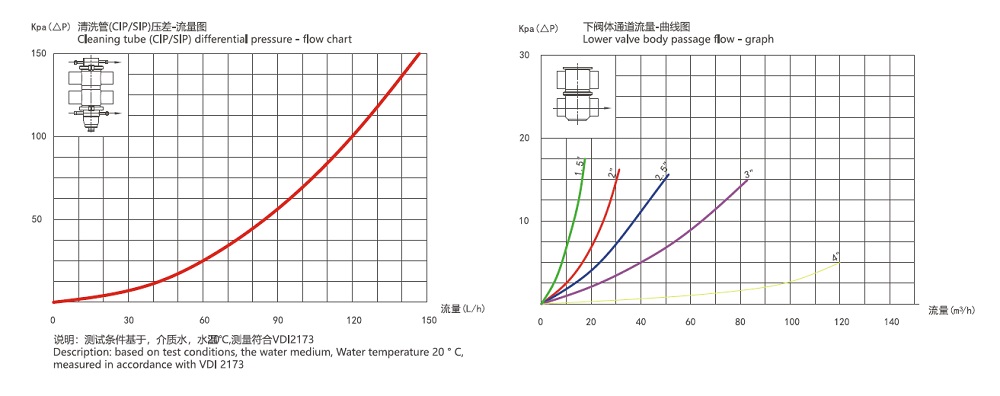

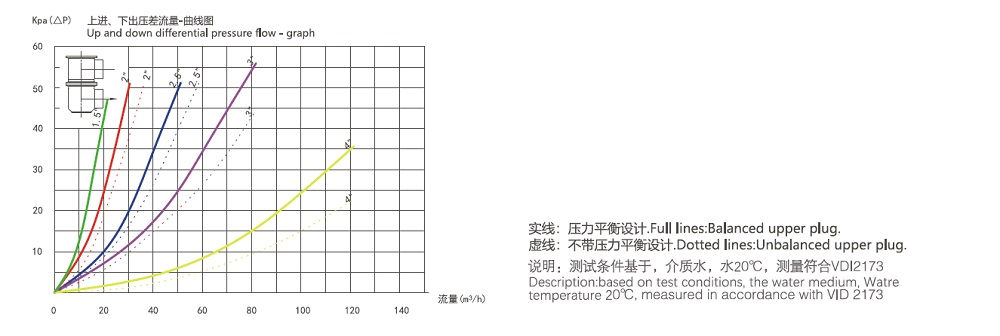

Mixproof valve performance curve

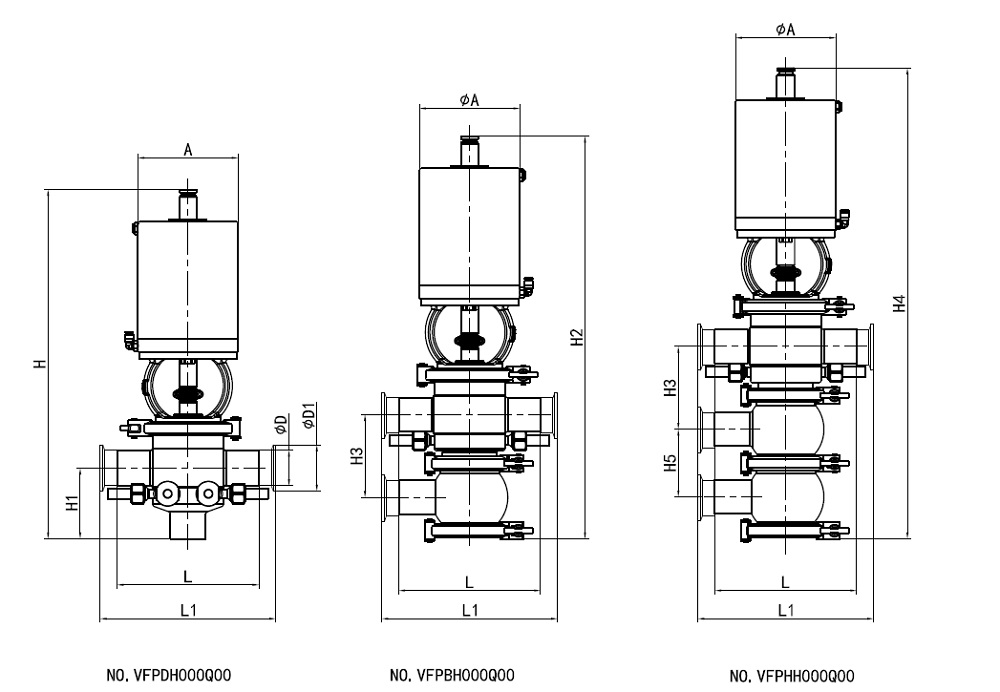

cip mixproof valve drawing

The unique flow mixproof valve adopts external introduction CIP and SIP cleaning and sterilization. Equipped with different valve bodies to meet different applications.

| File | Language | Size |

|---|---|---|

Mixproof valve catalogue Mixproof valve catalogue |

English | 31.08MB |

Sanitary valves catalogue Sanitary valves catalogue |

English | 30.2MB |