Donjoy factory building in 1993 year,located in Wenzhou,China

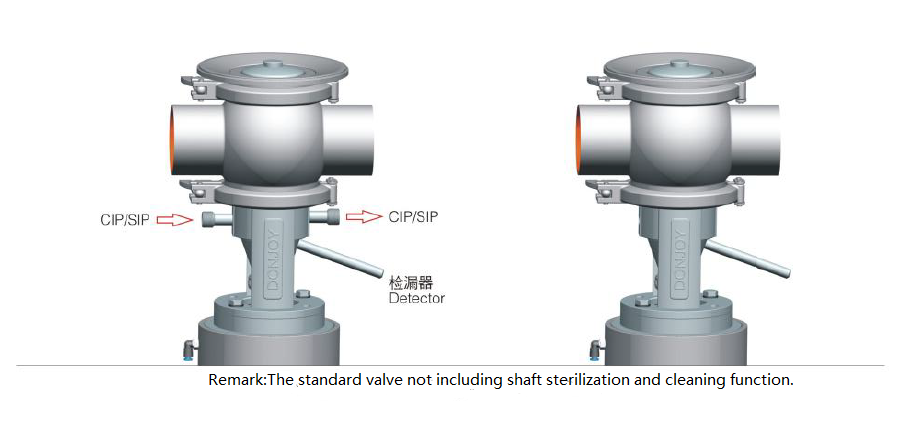

High clean sanitary SS316L mixproof tank bottom valve

The anti-mixing tank bottom valve is a high-cleanliness, online cleaning and sterilization integrated anti-mixing tank bottom valve.

Double seal protection, leakage can be found, self-draining, prevent media mixed contamination.

Technical Features

Connection method: Thread, clamp, welding, flange

Finish: Ra≤0.6μm; MP=Ra≤0.3μm; EP=Ra≤0.3μm

Material: 316L/1.4404, ASME BPE 316L 1.4435 NB2 Fe≤0.5%

Temperature: -20℃ to +150℃, Depending on the seal material

Connection standard: DIN SMS ISO IDF RJT BS4825 ASME BPE 3A DIN11864 DIN11853

Certification: FDA 177.2600; 3A-85-03; Glass II USP Glass VI Chapter 88; GB4806.11; EG VO/1935-2004; PED/97/23/EC.

What is a mixproof tank bottom valve?

Mixproof Tank Bottom Valve is a specific type of mixproof valve that is designed to connect to the bottom of a tank or vessel. It is commonly used in processing industries where product segregation and isolation are essential. The valve is installed within the tank so that it can drain or fill the tank without exposing the product to contamination.

This type of valve is an extremely efficient way of transferring products or flushing residual products from a tank without manually draining it. Mixproof tank bottom valves are also compact, making them an excellent space-saving solution. The valve's design allows it to be fully cleaned in place (CIP), making it easy to clean sterilize, and maintain without the need for disassembly.

Additionally, mixproof tank bottom valves are available with a variety of options such as dual isolation valves, in-tank cleaning and sterilization systems, and emergency shut-off valves. These options make it a versatile solution for a range of applications and industries, including food and beverage, pharmaceutical, chemical processing, and biotech industries.

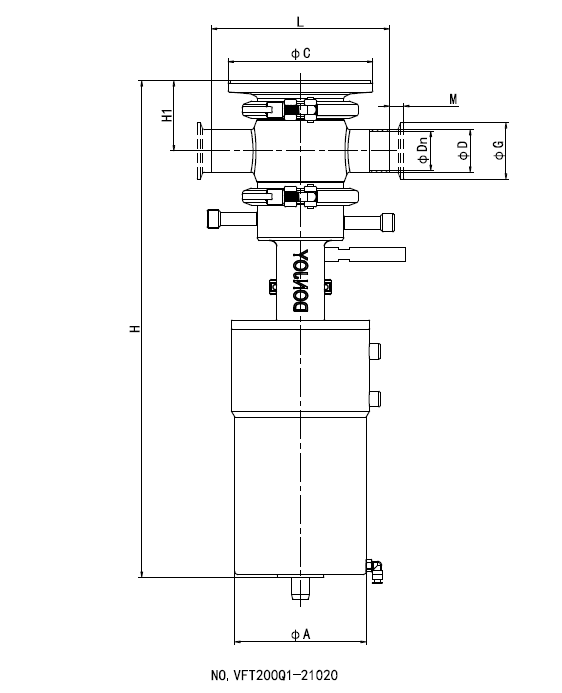

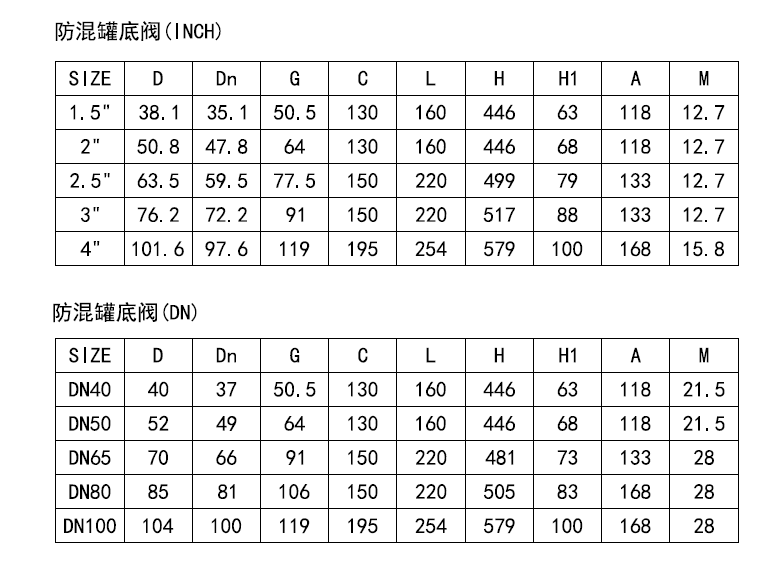

Product Drawing

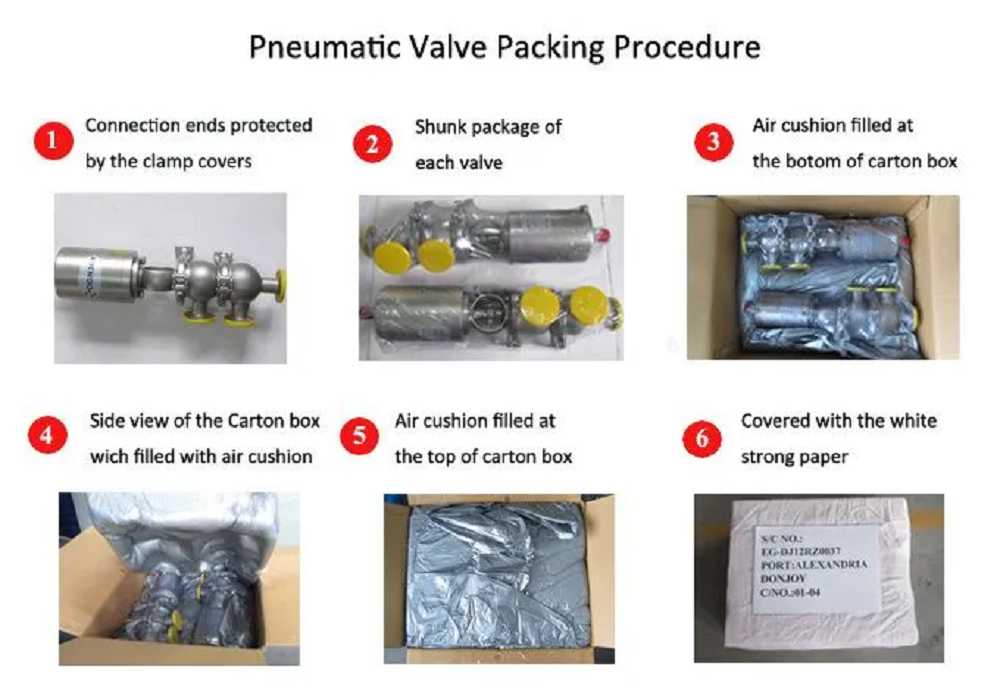

Package

Mixproof tank bottom valve affordable price a high-cleanliness, online cleaning CIP and sterilization SIP integrated.

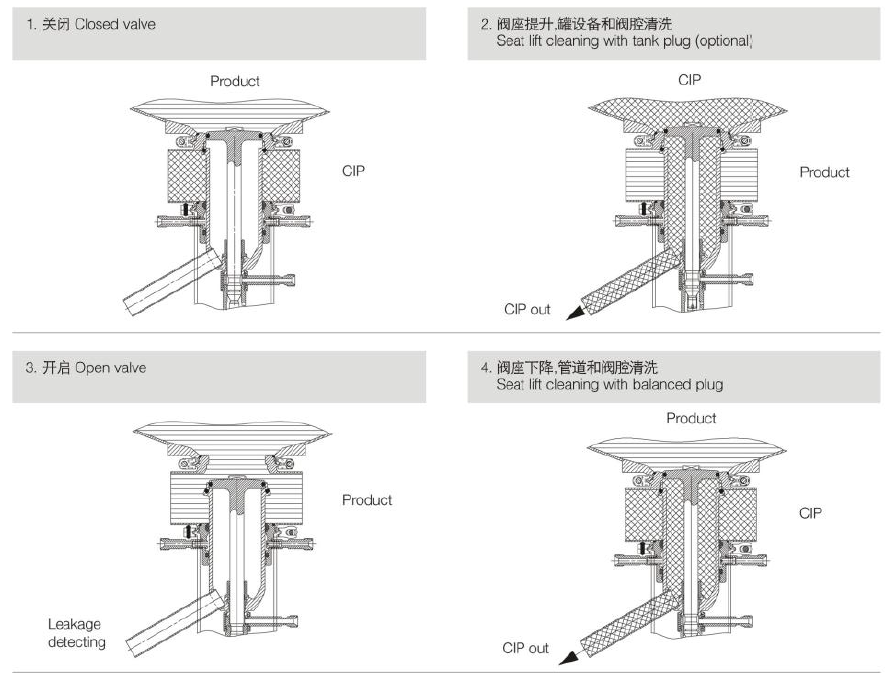

The mixproof tank bottom valve is remotely operated throught pneumatic actuator with compressed air,and it is constructted with two independent plugs,which will from a leakage chamber that interlinks to atmosphere under normal working status.When occasional failure of the liquids leakage happen ,liquids will flow into the chamber and be discharged at the outlet,here is will see if any conk our or seat seal deteced,preventing the possibility of products contamination due to leakge and conk out.When the valve is open ,the leakage chanber is closed.

| File | Language | Size |

|---|---|---|

Mixproof tank bottom valve catalogue Mixproof tank bottom valve catalogue |

English | 31.08MB |

Sanitary valves catalogue Sanitary valves catalogue |

English | 30.2MB |