Size: 1.5"-6", DN40-DN150

Pressure: vacuum to 10bar (1.0 MPa)

Sealing: EPDM FKM HNBR

Drive mode: pneumatic

Finish: Ra≤0.8um

Parts in contact with the media:AISI 316L

Other stainless steel parts:AISI 304

Balanced design

Working temperature:-10℃ to 130℃(140℃ for short periods or steilization)

Compressed air pressure:5.5 bar-7 bar

Air supply connection:R1/8"(BSP)

Donjoy factory building in 1993 year,located in Wenzhou,China

Dairy milk wine process food grade sanitary double seat mixproof valves manifolds

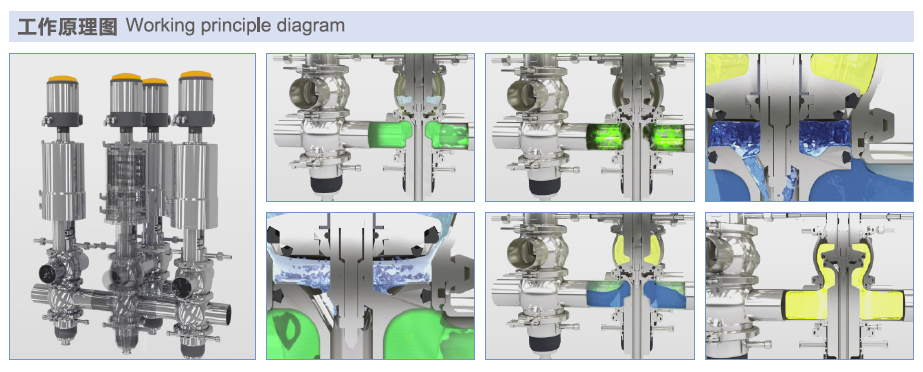

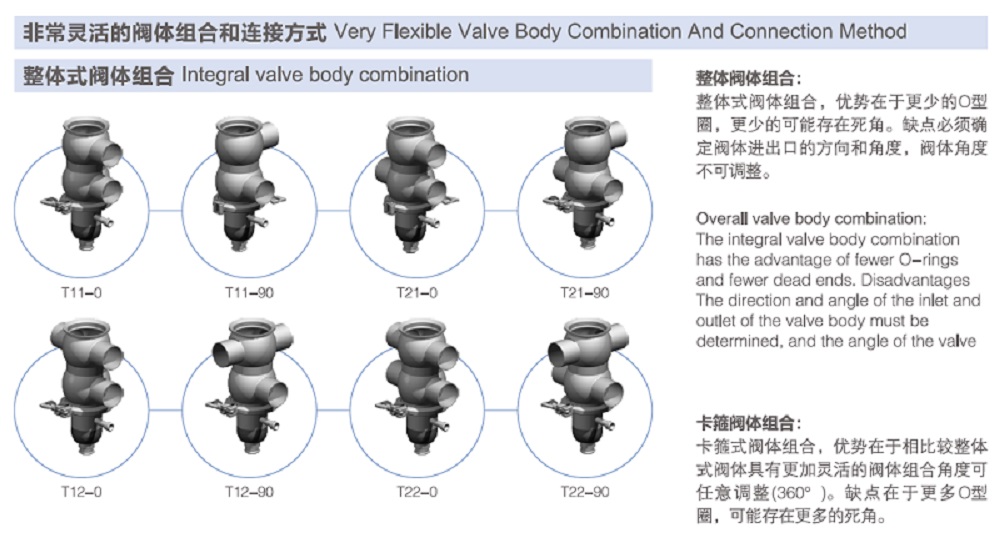

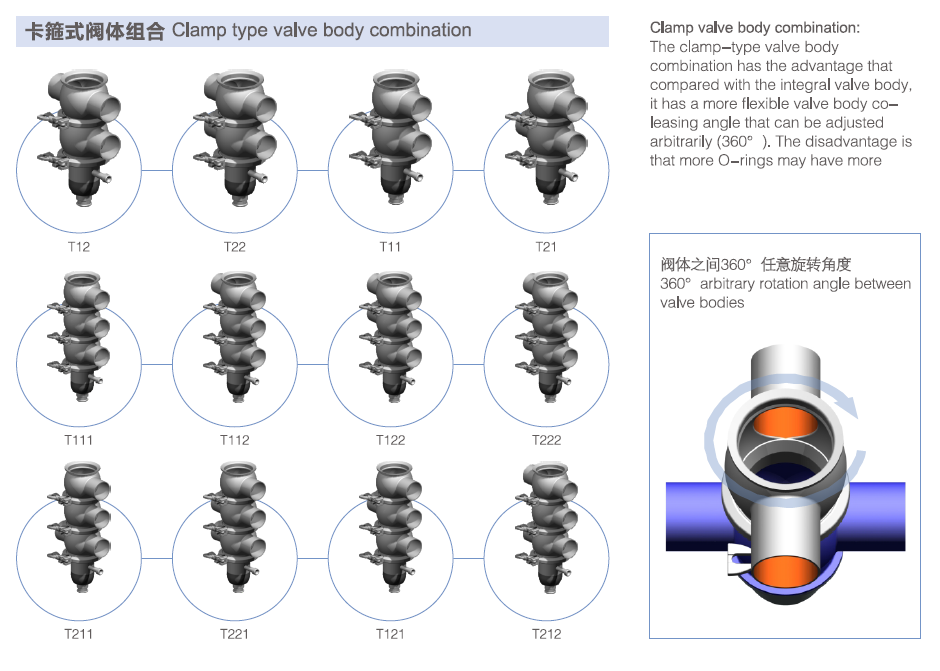

The double seat mixproof valve is a valve with technical characteristics such as online in-situ CIP cleaning, SIP sterilization, leakage detection, double-layer sealing protection, and prevention of the risk of medium contamination. It also has a very flexible valve body combination and Functional configuration such as valve control unit, feedback device, position sensor, etc. The design of the valve is completely based on the high cleanliness requirements of the United States 3-A-85-03 design.

What is mixproof valve?

Mixproof valve is a type of valve used in process industries to prevent the mixing of two different fluids or products. It consists of two valve seats, one on each side of the valve body, which are separated by a diaphragm or piston. This design allows for the simultaneous flow of two different fluids or products in opposite directions, without mixing, while also ensuring that there is no leakage between the two flow paths. Mixproof valves are commonly used in industries such as dairy, food and beverage, pharmaceuticals, and chemical processing. All in all\,this design helps to prevent contamination and maintain product quality and safety during processing.

How do mixproof valves work?

Mixproof valves work by using a double-seat design to isolate two different fluids or products passing through the valve. The two seats or valve plugs are separated by a flexible diaphragm or piston, which can move up and down to open or close each seat. This allows the valve to have two separate flow paths, one for each fluid, which are isolated from each other. When the valve is closed, the diaphragm creates a seal between the two flow paths, preventing any mixing or cross-contamination between the two fluids.

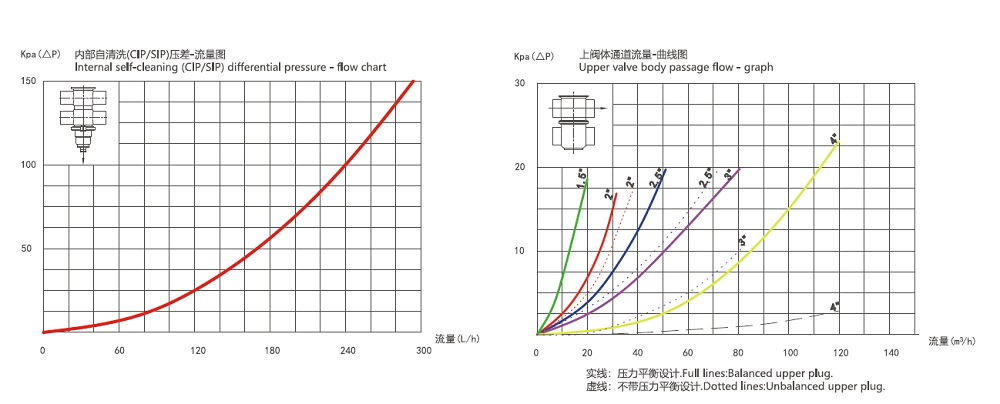

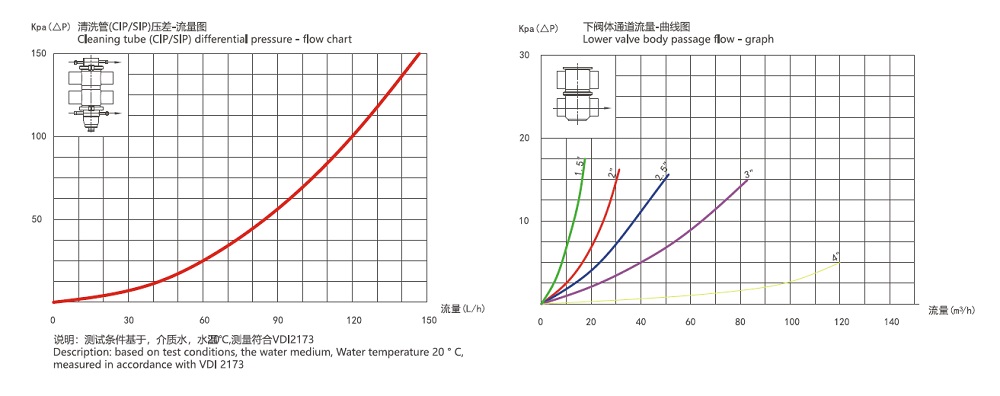

During operation, the valve position is controlled by an actuator with compressed air, which moves the diaphragm up and down to open or close each seat. When one seat is open, the other is closed, ensuring that the two products don't mix. Mixproof valves are designed to be CIP (clean in place) and SIP compatible, which makes it easier to clean and sanitize the valve between batches or product changeovers without disassembling it, reducing downtime during production.

Technical Features

Material: 316L/1.4404, ASME BPE 316L 1.4435 NB2 Fe≤0.5%

Finish: Ra≤0.8μm;Ra≤0.6μm; MP=Ra≤0.3μm; EP=Ra≤0.3μm

Connection method: Thread, clamp, welding, flange

Temperature: -20℃ to +150℃, Depending on the seal material

Connection standard: DIN SMS ISO IDF RJT BS4825 ASME BPE 3A DIN11864 DIN11853

Certification: FDA 177.2600; 3A-85-03; Glass II USP Glass VI Chapter 88; GB4806.11; EG VO/1935-2004; PED/97/23/EC.

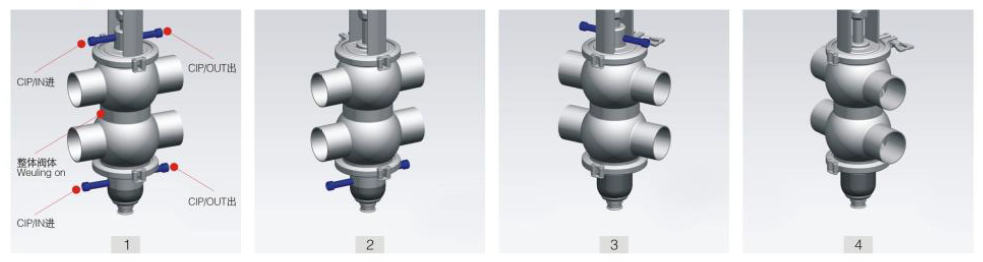

Cleaning/Sterilization Parts for options

1. Upper and lower steam clenaing/ sterilization +seat lift cleaning

2. The lower stem cleaning/sterilization +seat lift cleaning

3. The umpper stem cleaning/sterilization +seat lift cleaning

4. Seat lift cleaning (Basic)

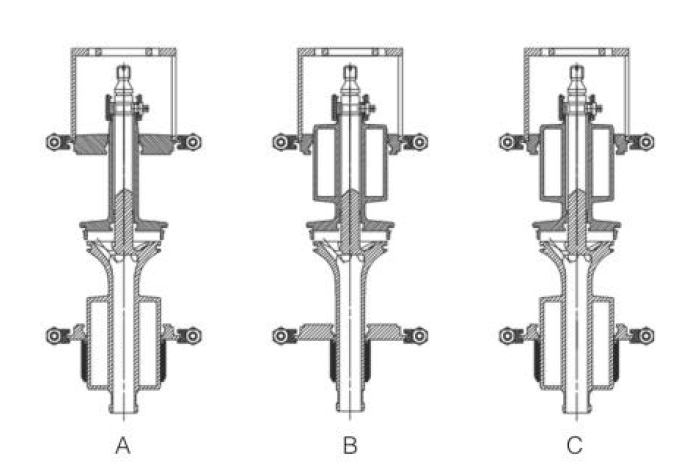

Pressure balance design selection

A. Upper steam balance

B. Lower steam balance

C. Upper and lower steam balabce

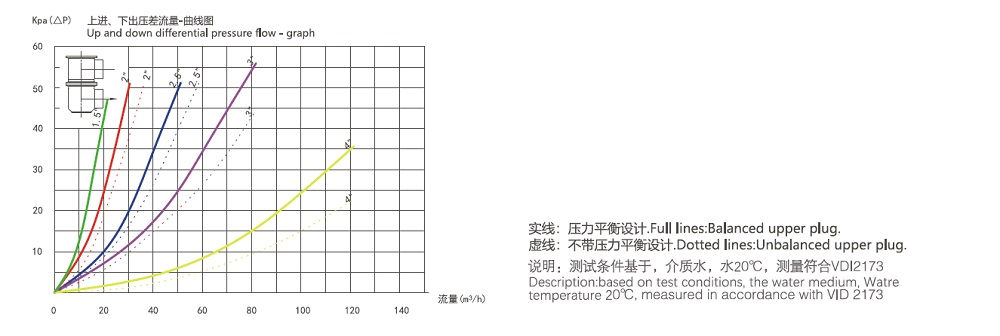

Double seat mixproof valve pressure difference

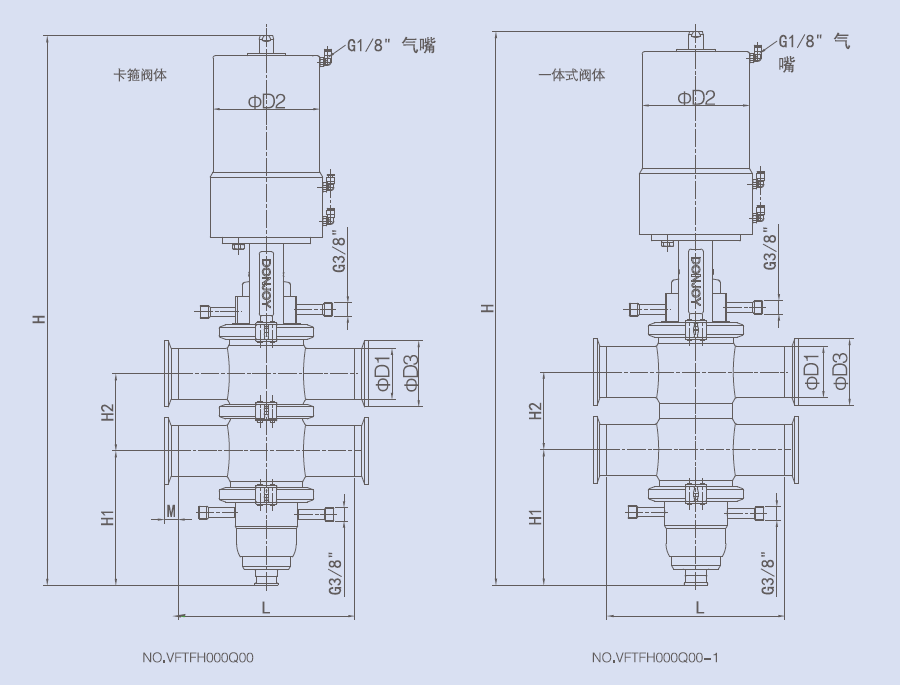

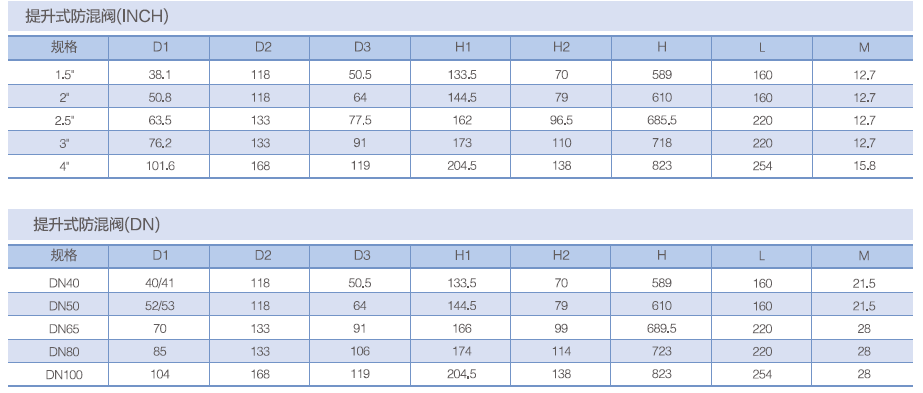

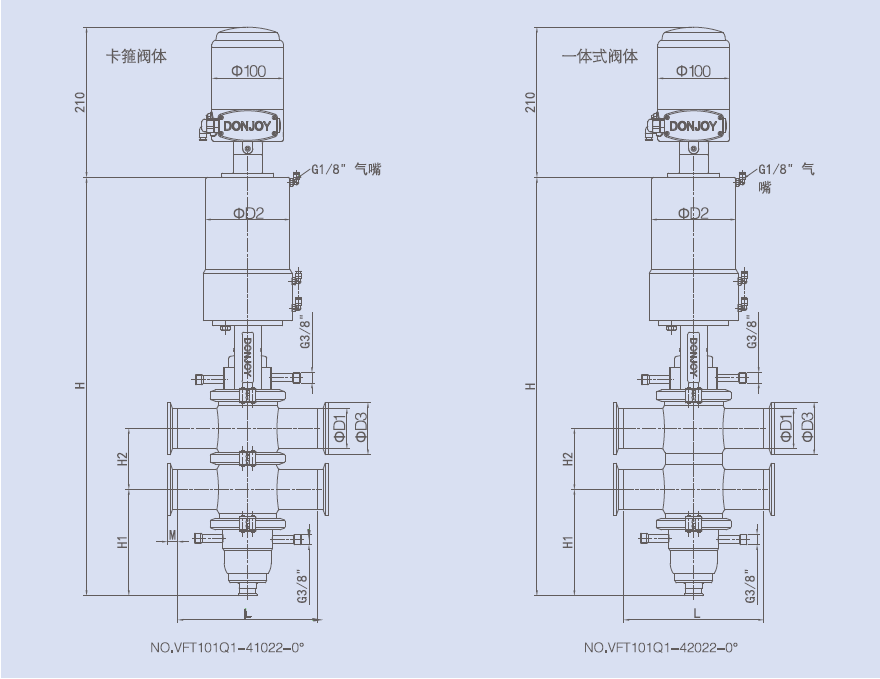

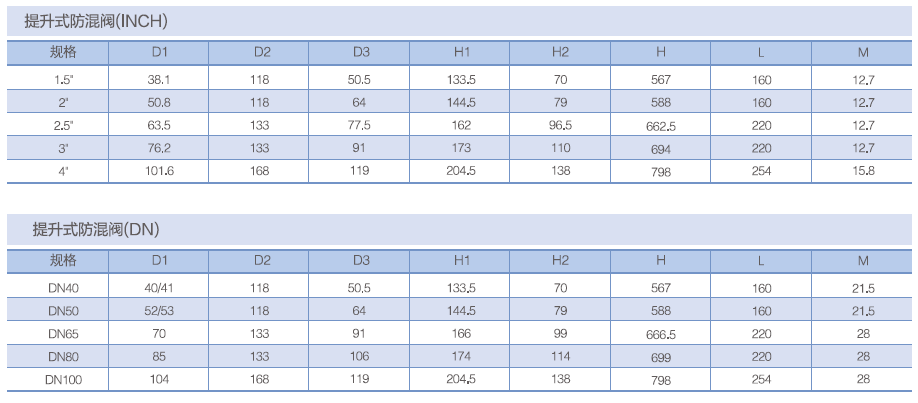

Product Drawing

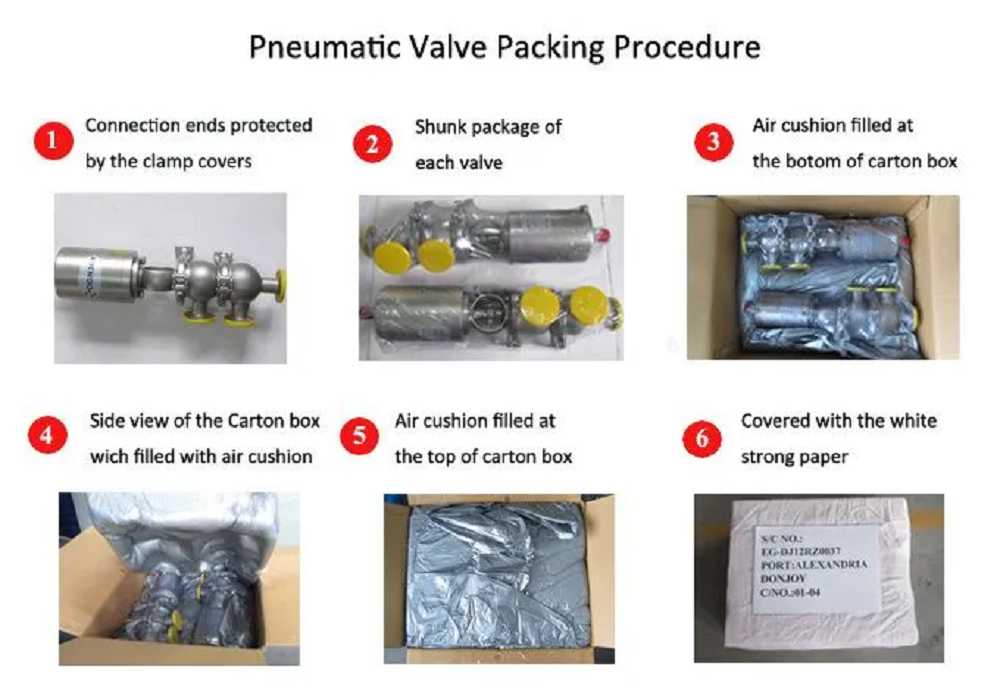

Package

By air: carton box

By sea/train:Wooden box

Many anti-mixing valves are used in valve array systems, because the valve has the technical characteristics of online in-situ CIP cleaning, sterilization, self-draining, no dead ends, no retention, etc., and has very flexible configurations such as position feedback devices and valves Automatic control systems such as control units and position sensors.

| File | Language | Size |

|---|---|---|

Mixproof valve catalogue Mixproof valve catalogue |

English | 31.08MB |

Sanitary valves catalogue Sanitary valves catalogue |

English | 30.2MB |