Technical Data Sheet

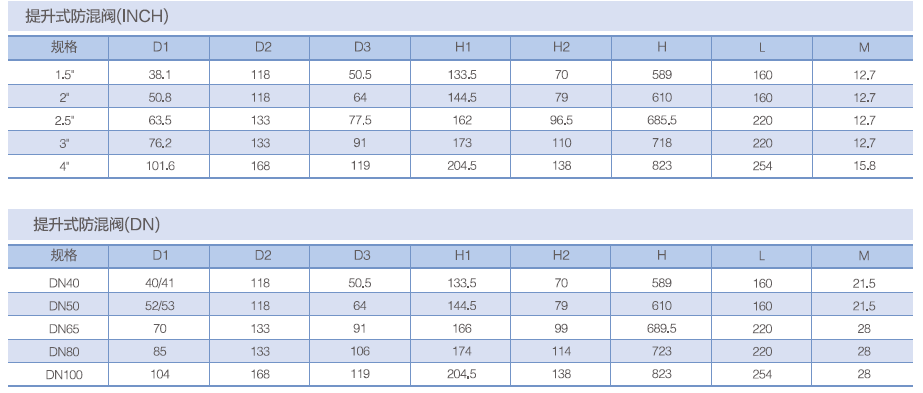

Specification range 1.5 "-6"/DN40-DN150

Maximum pressure 6bar

Minimum pressure is completely vacuum

Work temperature -10 ℃ to 120 ℃ (available for 150 ℃)

Applicable medium water, oil, gas and other media

Interface type card hoop, welding, thread, flange

Air source pressure 5-7bar Air source interface G 1/4

Line detection pressure 6bar Pneumatic detection pressure 6bar

Part

AISI 304/1.4301, 316L/1.4404

Over -flow sealing part EDPM (FPM optional)

Substation of smoothness and sandblasting, sandblasting

Inner surface is smooth and light (polished), RA <0.8um

Donjoy factory building in 1993 year,located in Wenzhou,China

US-3A CE Sanitary double seat mixproof valve with stainless steel 316L matrix

Technical Data Sheet

Specification range 1.5 "-6"/DN40-DN150

Maximum pressure 6bar

Minimum pressure is completely vacuum

Work temperature -10 ℃ to 120 ℃ (available for 150 ℃)

Applicable medium water, oil, gas and other media

Interface type card hoop, welding, thread, flange

Air source pressure 5-7bar Air source interface G 1/4

Line detection pressure 6bar Pneumatic detection pressure 6bar

Part

AISI 304/1.4301, 316L/1.4404

Other steel components AISI 304/1.4301

Over -flow sealing part EDPM (FPM optional)

Substation of smoothness and sandblasting, sandblasting

Inner surface is smooth and light (polished), RA <0.8um

What is a mixproof valve?

Mixproof valve is a type of valve used in process industries to prevent the mixing of two different fluids or products. It consists of two valve seats, one on each side of the valve body, which are separated by a diaphragm or piston. This design allows for the simultaneous flow of two different fluids or products in opposite directions, without mixing, while also ensuring that there is no leakage between the two flow paths. Mixproof valves are commonly used in industries such as dairy, food and beverage, pharmaceuticals, and chemical processing. All in all\,this design helps to prevent contamination and maintain product quality and safety during processing.

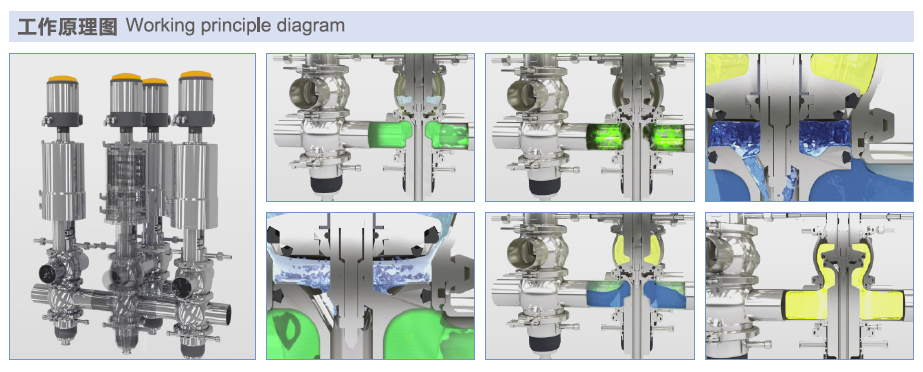

How do mixproof valves work?

Mixproof valves work by using a double-seat design to isolate two different fluids or products passing through the valve. The two seats or valve plugs are separated by a flexible diaphragm or piston, which can move up and down to open or close each seat. This allows the valve to have two separate flow paths, one for each fluid, which are isolated from each other. When the valve is closed, the diaphragm creates a seal between the two flow paths, preventing any mixing or cross-contamination between the two fluids.

During operation, the valve position is controlled by an actuator with compressed air, which moves the diaphragm up and down to open or close each seat. When one seat is open, the other is closed, ensuring that the two products don't mix. Mixproof valves are designed to be CIP (clean in place) and SIP compatible, which makes it easier to clean and sanitize the valve between batches or product changeovers without disassembling it, reducing downtime during production.

Technical Features

Material: 316L/1.4404, ASME BPE 316L 1.4435 NB2 Fe≤0.5%

Finish: Ra≤0.8μm;Ra≤0.6μm; MP=Ra≤0.3μm; EP=Ra≤0.3μm

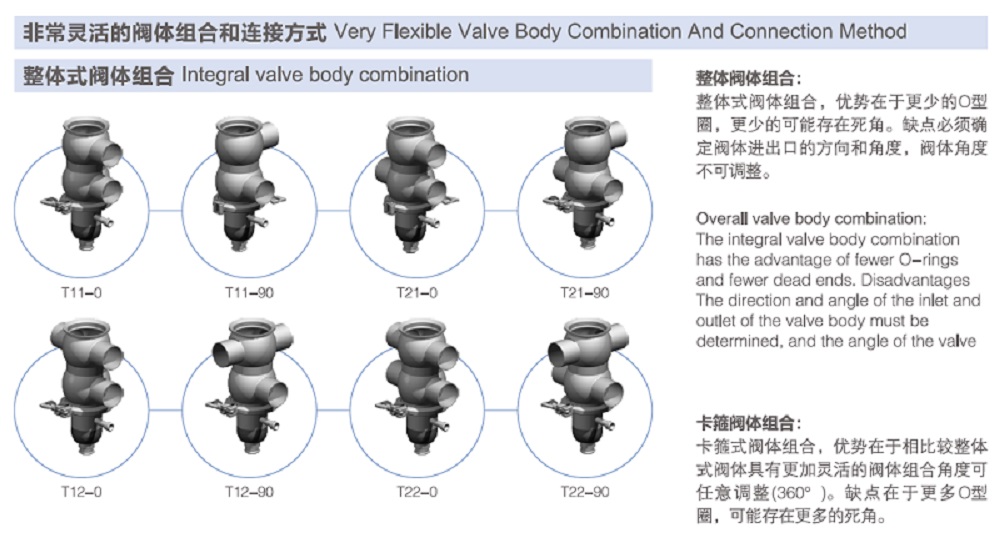

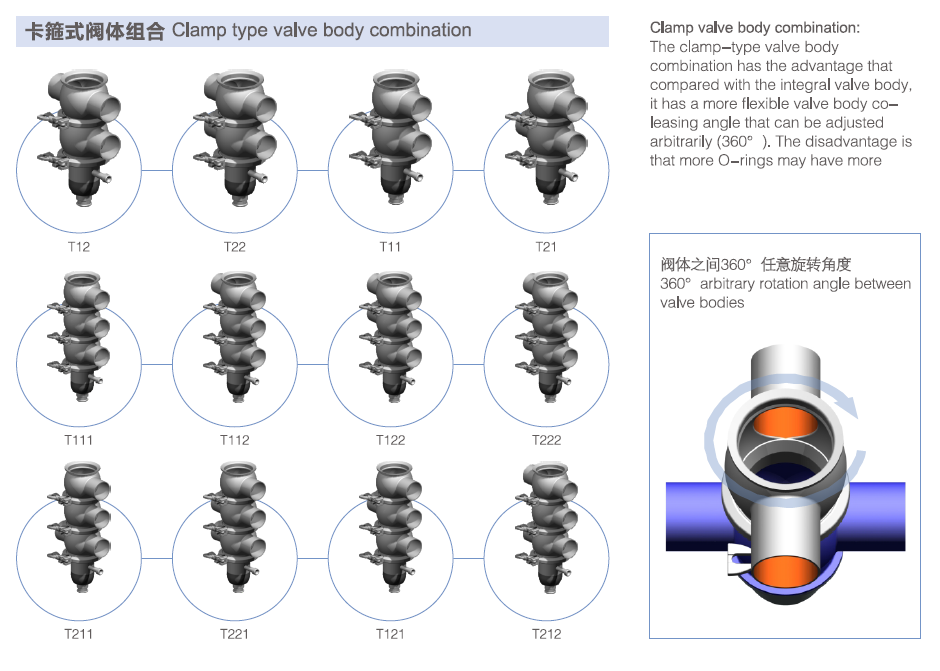

Connection method: Thread, clamp, welding, flange

Temperature: -20℃ to +150℃, Depending on the seal material

Connection standard: DIN SMS ISO IDF RJT BS4825 ASME BPE 3A DIN11864 DIN11853

Certification: FDA 177.2600; 3A-85-03; Glass II USP Glass VI Chapter 88; GB4806.11; EG VO/1935-2004; PED/97/23/EC.

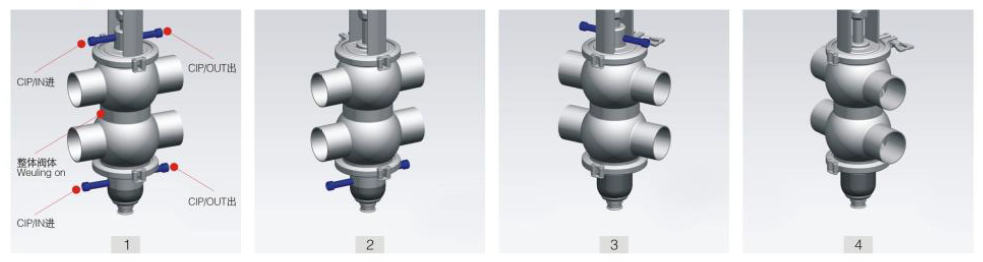

Cleaning/Sterilization Parts for options

1. Upper and lower steam clenaing/ sterilization +seat lift cleaning

2. The lower stem cleaning/sterilization +seat lift cleaning

3. The umpper stem cleaning/sterilization +seat lift cleaning

4. Seat lift cleaning (Basic)

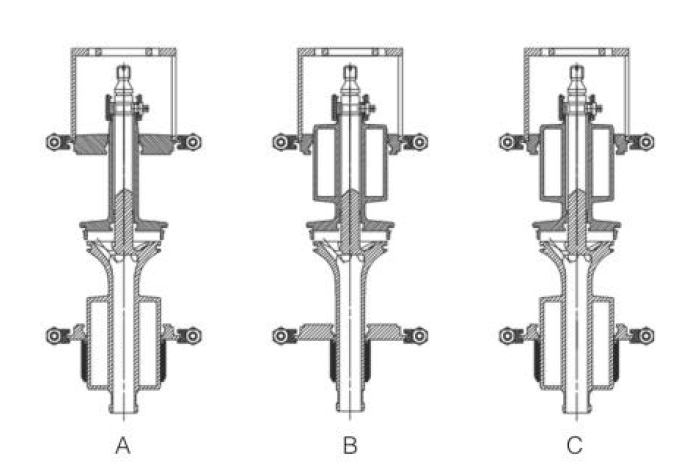

Pressure balance design selection

A. Upper steam balance

B. Lower steam balance

C. Upper and lower steam balabce

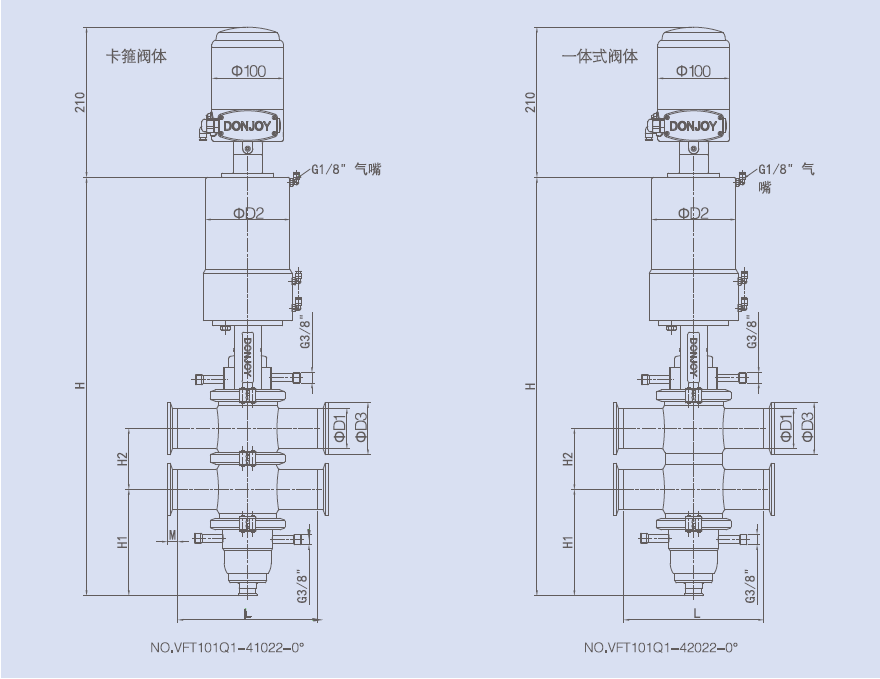

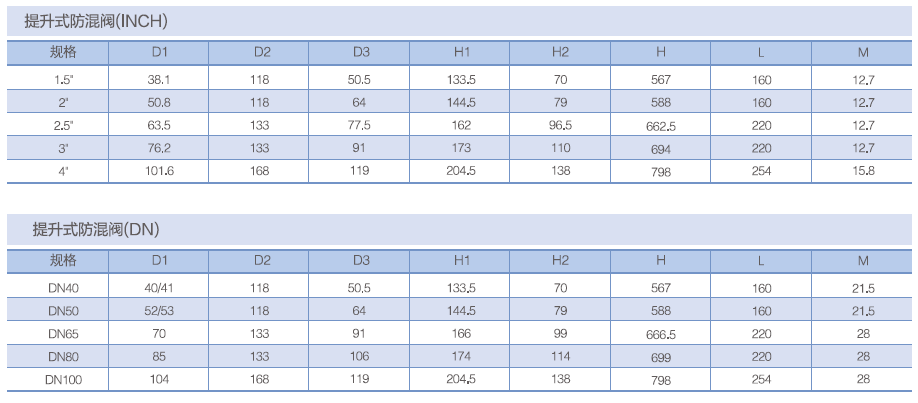

Mixproof valve Product Drawing

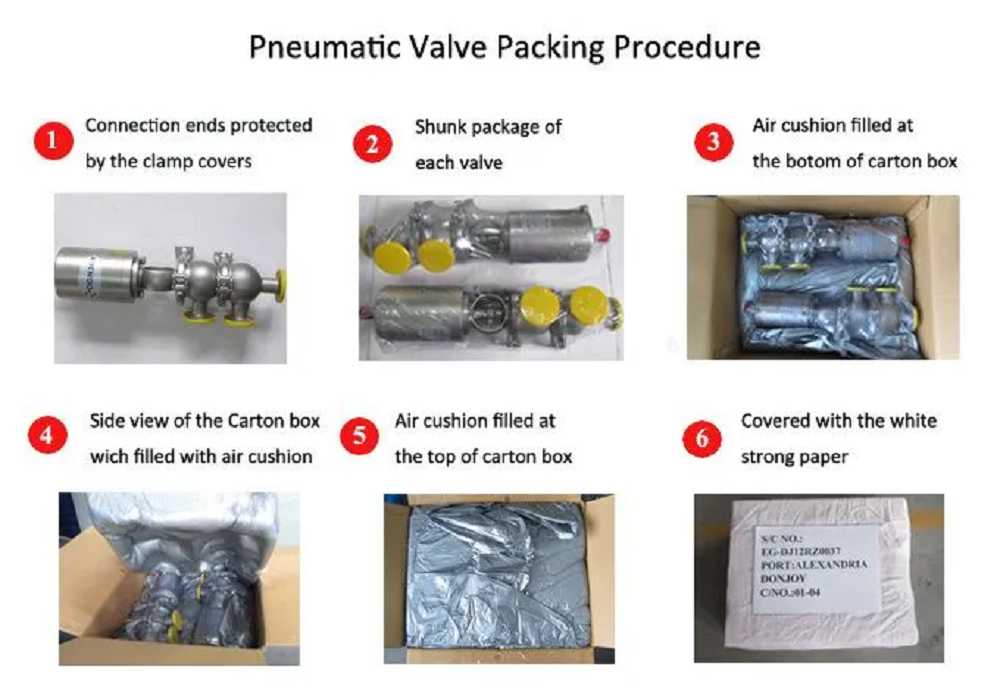

Package

By air: carton box

By sea/train:Wooden box

Sanitary double seat mixproof valve

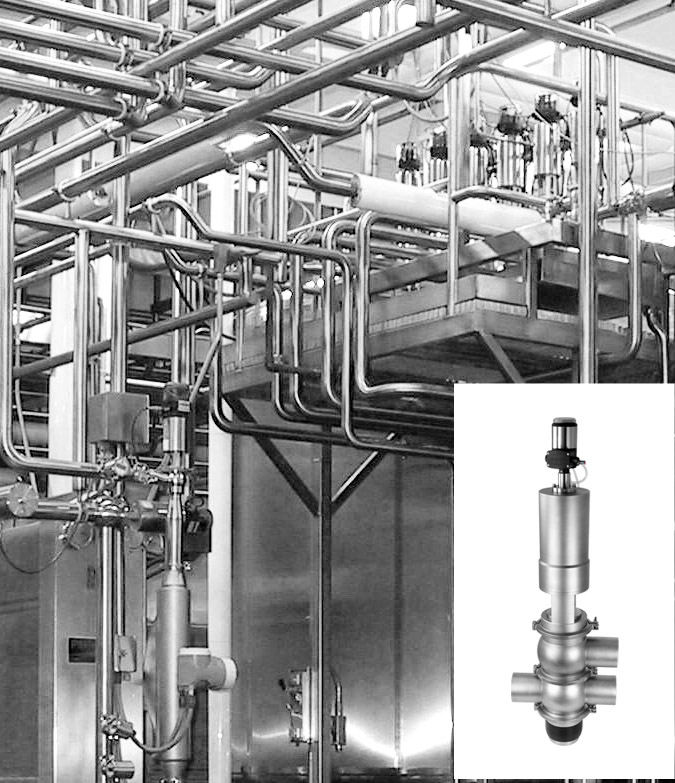

In the field of modern industry, fluid control is a vital task. However, problem that different fluids mixed has always plagued many companies. To solve this problem, Donjoy Technology Co., Ltd. has developed an excellent big mixing proof valve, which will become a powerful assistant for industrial safety and production efficiency.

First, let's have insight into the technical characteristics of big mixing proof valve. The most significant advantage is that it can be cleaned and sterilized by the online original CIP. This technical characteristics can completely clean and disinfect the valve without disassembly. This not only greatly reduces the risk of maintenance costs and production interruptions, but also ensures the hygiene and safety of the production environment, and effectively prevents bacterial breeding and cross -pollution.

In addition, mixing proof valve also have the technical characteristics of self -evaporation, no dead ends and non-retention. When the valve is closed, it can automatically empty the internal residual fluids to avoid the occurrence of dead ends and retention phenomena. This not only effectively prevents fluid mixing, but also ensures the cleaning and fluency of the pipeline system, which further improves production efficiency and product quality.

Of course, in addition to excellent technical characteristics, large -scale anti -hybrid valves also have very flexible configuration options. It can be combined with location feeders, valve control units, position sensors and other self -control systems to achieve precise valve control and monitoring. This flexible configuration enables the anti -hybrid valve to personalize according to different production needs and scenes to better meet the actual needs of the enterprise.

In practical applications, the anti -hybrid valve has been recognized and praised by users. Whether in food, medicine, chemical industry or other industries, it can exert excellent performance and bring significant benefits to enterprises. Many companies have said that the problem of fluid hybrid in the production process of large -scale anti -mixtures will be effectively solved, and production efficiency and quality will be significantly improved.

| File | Language | Size |

|---|---|---|

Mixproof valve catalogue Mixproof valve catalogue |

English | 31.08MB |

Sanitary valves catalogue Sanitary valves catalogue |

English | 30.2MB |