16 Wed 2025

16 Wed 2025

Sanitary butterfly valves are mainly used in various pipeline media cleaning systems to reduce damage to pipeline media and are an important part of ensuring efficient and safe operation of fluid control systems.

When choosing sanitary butterfly valve suitable for the food industry, we can consider the following factors:

When applied to the food industry, first determine whether the medium is liquid or powder. If the medium is liquid, use normal sanitary butterfly valves or sanitary mixproof butterfly valves. If the medium is powder, suggest powder sanitary butterfly valve.

The materials of sanitary food-grade regular butterfly valves are stainless steel 304 and 316L.

Stainless steel 316L has better corrosion resistance and high temperature resistance than stainless steel 304. For application areas with higher food-grade working conditions such as high temperature and corrosion resistance, SS316L can be selected.

SS304 is more cost-effective and suitable for general food processing.

The main seal materials are EPDM, silicone, Viton/FPM, NBR and HNBR.

* EPDM is suitable for most working conditions, such as temperature -10℃ to 130℃, with good corrosion resistance, good acid and alkali resistance, long life and lowest cost.

* Viton/FPM has the best corrosion resistance and acid and alkali resistance, which is better than other materials EPDM, SILICON, NBR and HNBR. It is suitable for temperatures from -10℃ to 130℃ and has the highest cost.

* Silicone is suitable for high temperatures, but its acid and alkali resistance and various chemical agents are poor. The cost is higher than EPDM

* NBR is best for oil products, good wear resistance, temperature -5℃ to 130℃, low cost performance, similar to EPDM.

* HNBR is best for oil products, good acid and alkali resistance and various chemical agents, such as temperature -10℃ to 130℃, and the cost is slightly higher than EPDM.

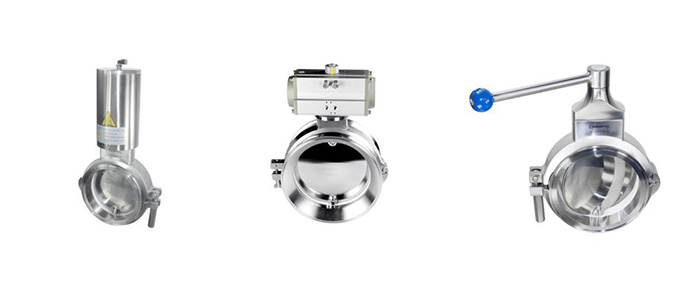

Food-grade sanitary butterfly valves has four types: normal butterfly valves, three-piece butterfly valves, powder butterfly valves and mixproof butterfly valves.

You can choose manual butterfly valves, pneumatic butterfly valves and electric butterfly valves according to the working conditions.

* Normal hygienic butterfly valves are suitable for occasions with relatively low hygiene requirements, such as ordinary food processing, water treatment, etc., and do not require frequent disassembly and cleaning.

* Three-piece butterfly valves are used in industries with extremely high hygiene requirements, such as pharmaceuticals, bioengineering, high-end food and beverages, etc., and require frequent cleaning and disinfection.

* Mixproof butterfly valves are mainly suitable for most fluid process applications in the food, pharmaceutical and fine chemical industries. As an important process for separating materials, they are widely used in CIP cleaning systems to separate cleaning solutions.

* Powder butterfly valves are used in powder conditions.

Ensure that the sanitary butterfly valves complies with local and industry safety standards and regulations, such as FDA and CE certification, which is related to product safety and quality.

There are four main connection methods for sanitary butterfly valves: welding, clamps, threads, and flanges.

Choose the valve size according to the actual working conditions, size 1/2"-12", DN10-DN300.

Mechanical polishing, electronic polishing and sandblasting.

The standard is Ra1.2um for the outer surface and Ra 0.8um for the inner surface.

If the polishing level is higher, it can reach electrolytic polishing SF4 Ra 0.38um

DONJOY sanitary butterfly valves has 30 years of experience. The valve body and valve disc adopt the integral forging process, and the CNC machining center completes the molding in one step to ensure the machining accuracy of the valve body and valve disc.

How to choose sanitary butterfly valves suitable for the food industry?

The Advantages of Manual Regular Butterfly Valves in Industrial Applications