13 Wed 2022

13 Wed 2022

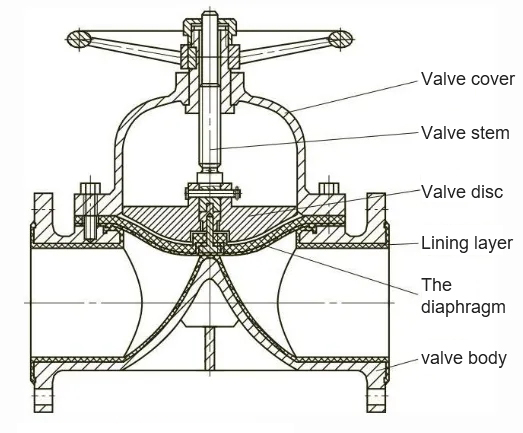

The most prominent feature is that the diaphragm valve separates the inner cavity of the lower valve body from the inner cavity of the upper bonnet, so that the valve stem, valve disc and other parts above the diaphragm are not corroded by the medium, eliminating the need for packing and sealing structure, and will not produce medium outside. leak.

1. The diaphragm made of soft seals such as rubber or plastic has better sealing performance. Since the diaphragm is a wearing part, it should be replaced regularly according to the characteristics of the medium.

2. Limited by the diaphragm material, the diaphragm valve is suitable for low pressure and relatively low temperature occasions.

3. Diaphragm valves can be divided into six types according to the structure: house type, DC type, cut-off type, straight-through type, gate type and right-angle type; the connection form is usually flange connection; according to the driving mode, it can be divided into manual, electric and pneumatic There are three types, among which the pneumatic drive is divided into three types: normally open, normally closed and reciprocating.

4. Generally, it should not be used in pipelines with temperatures higher than 60 degrees and conveying organic solvents and strong oxidizing media, nor in pipelines with higher pressure.

The structure of the diaphragm valve is very different from that of ordinary valves. It is a new type of valve and a special form of shut-off valve. Its opening and closing part is a diaphragm made of soft The inner cavity of the cover and the driving part are separated, and are now widely used in various fields. Commonly used diaphragm valves include rubber-lined diaphragm valves, fluorine-lined diaphragm valves, unlined diaphragm valves, and plastic diaphragm valves.

Why sanitary stainless steel butterfly valves corrosion resistant?