Dairy milk brewery tank sanitary sample valves manufacturer

The sampling valve strictly complies with the American 3-A standard, which includes various designs such as aseptic sampling valve, non-retention sampling valve, yogurt sampling valve, etc.

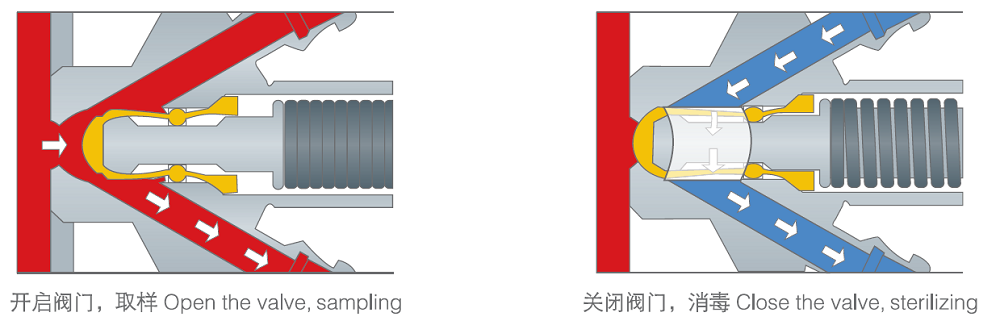

Aseptic sampling valve operating principles

The aseptic sampling valve is designed for sterilization before and after each sampling

Open:Sampling, the manual valve is opened by rotating the handle (adjustable valve) or by activating the lever(on/off valve).The stem and the memrabne are then retracted,allowing liquid to pass.

Closed-Sterilizing,the built in spring closes the valve and keeps the channel open between the hoses though reverse process in order to sterilize.If using by steam, a small pressure relief valve (optional) on the outlet is recommended.

Standard design:the aspetic sampling valve consists of three parts, a valve body, a handle and a membrane.The rubber memebrane is placed on the stem of the valve and works as a strectchable plug.

The aspetic sampling valve is applied to beer,milk ,beverage,fruit juice,pharmacy industries etc.

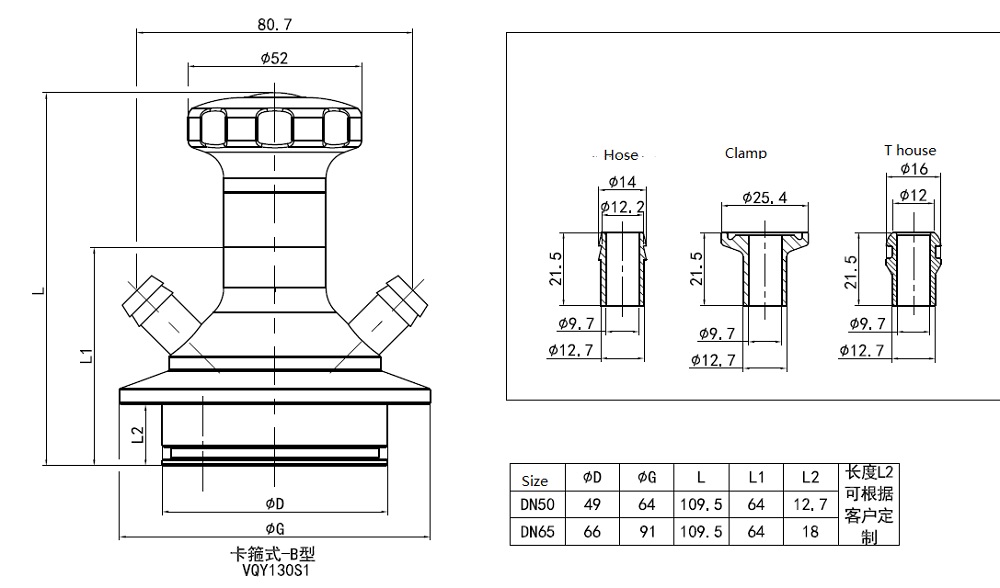

Connections:Thread, welding,clamp

Handle: Turning handle ,removable key

Seal material

Seal material

Max. Temperature: 130℃(EPDM)

Max. Temperature: 150℃(PTFE)

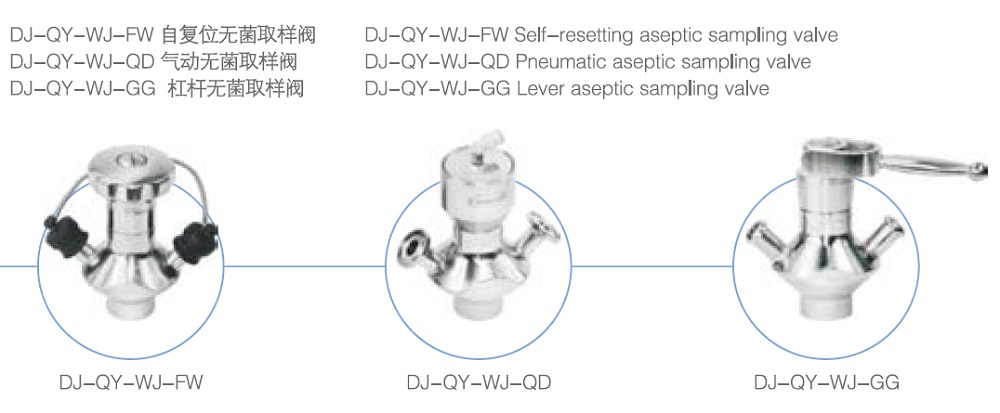

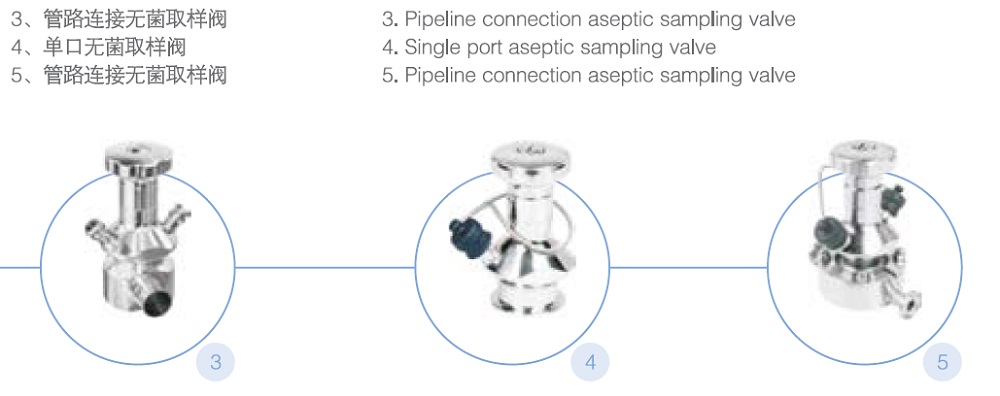

Different type of aseptic sampling valve

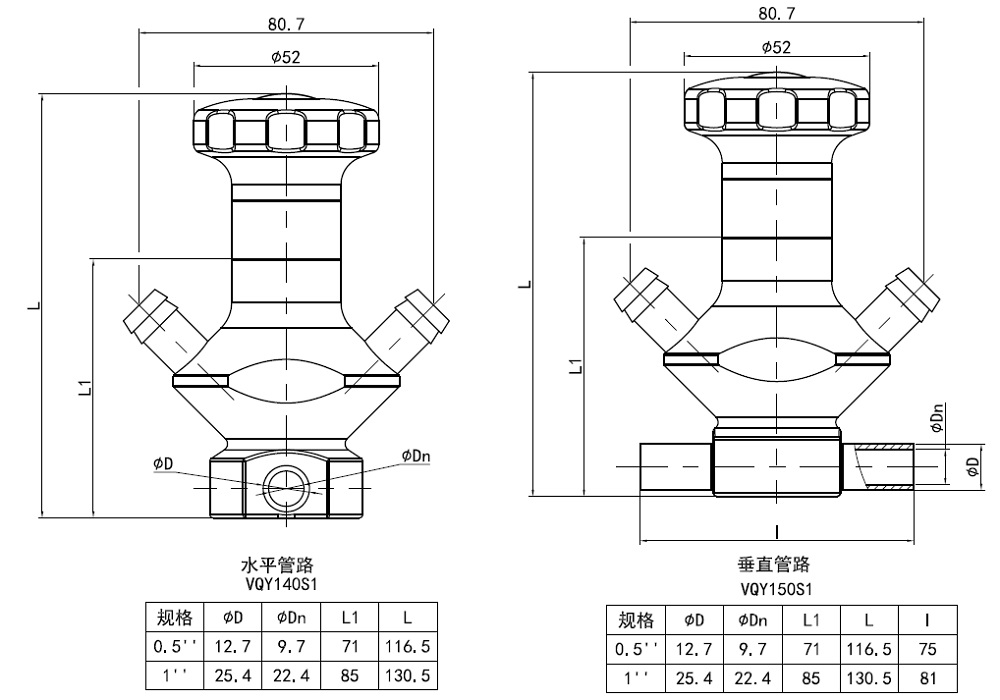

Sample port inlet and outlet selection:

Tank connection way:

Different valve body configurations

| File | Language | Size |

|---|---|---|

Sample valve catalogue Sample valve catalogue |

English | 16.6MB |

Sanitary valves catalogue Sanitary valves catalogue |

English | 30.2MB |