The sampling valve strictly complies with the American 3-A standard, which includes various designs such as aseptic sampling valve, non-retention sampling valve, yogurt sampling valve, etc.

Aseptic sampling valves are special valves designed for aseptic sampling of liquids in sensitive industrial processes for processes in the food and beverage industry.

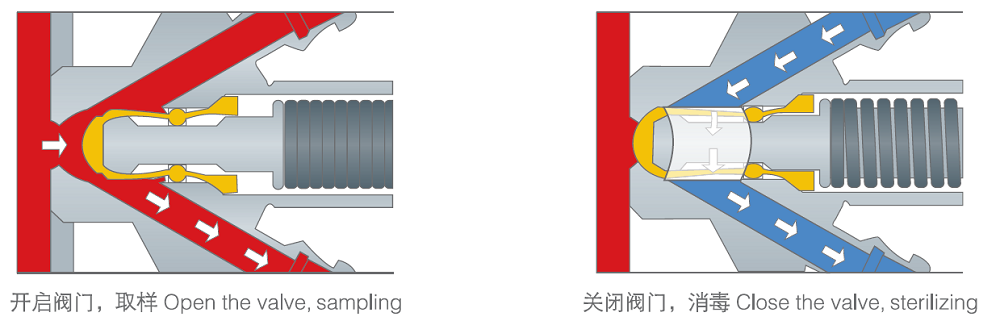

Aseptic sampling valve operating principles

The aseptic sampling valve is designed for sterilization before and after each sampling

Open:Sampling, the manual valve is opened by rotating the handle (adjustable valve) or by activating the lever(on/off valve).The stem and the memrabne are then retracted,allowing liquid to pass.

Closed-Sterilizing,the built in spring closes the valve and keeps the channel open between the hoses though reverse process in order to sterilize.If using by steam, a small pressure relief valve (optional) on the outlet is recommended.

Standard design:the aspetic sampling valve consists of three parts, a valve body, a handle and a membrane.The rubber memebrane is placed on the stem of the valve and works as a strectchable plug.

The aspetic sampling valve is applied to beer,milk ,beverage,fruit juice,pharmacy industries etc.

Connections:Thread, welding,clamp

Handle: Turning handle ,removable key

Seal material

Seal material

Max. Temperature: 130℃(EPDM)

Max. Temperature: 150℃(PTFE)

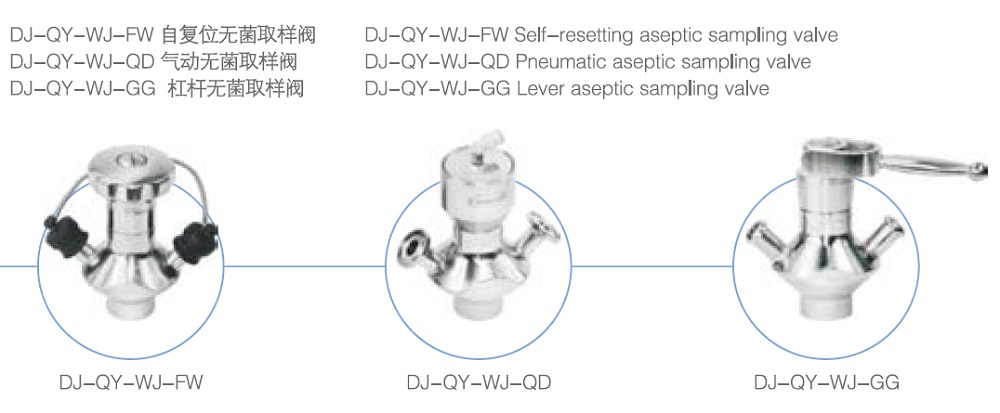

Different type of aseptic sampling valve

Sample port inlet and outlet selection:

Sample port inlet and outlet selection:

Tank connection way:

Different valve body configurations

| File | Language | Size |

|---|---|---|

Sampling valve catalogue Sampling valve catalogue |

English | 16.6MB |

Sanitary valves catalogue Sanitary valves catalogue |

English | 30.2MB |